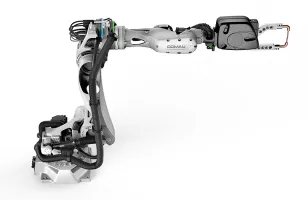

- Industrial (Articulated) Robots

- YASKAWA

- SP80

- Specifications

YASKAWA SP80 Specifications

Ranked Nr. 15 of 408 Industrial (Articulated) Robots

The Yaskawa MOTOMAN SP80 is a compact spot welding and handling robot known for its efficiency and versatility. With an 80 kg payload capacity, including the C-adapter, and a 2236 mm working range, it is well-suited for high-density robot lines in car body construction and the economical welding of small subassemblies. Its compact design allows for space-saving installations on various positioners, making it ideal for environments where space is at a premium.

Powered by the advanced MOTOMAN YRC1000 controller, the SP80 features the latest Yaskawa Sigma-7 servo drive technology. This technology provides high dynamics and energy efficiency, contributing to exceptional cycle times and overall operational efficiency. The robot's six-axis configuration and repeatability of 0.03 mm ensure precise and reliable performance, essential for high-quality welding and handling tasks.

The SP80's design emphasizes flexibility with multiple mounting options, including ceiling, wall, and floor configurations. This flexibility, combined with its high-speed capabilities—up to 350 °/s on the T axis—makes it a robust solution for various industrial applications, particularly in automotive manufacturing where precise and efficient spot welding is crucial.

| Repeatability | 0.03 mm |

| Reach | 2236 mm |

| Payload | 80 kg |

SP80 Alternatives

See all 473 Industrial (Articulated) Robots

ABB IRB 1600

Payload 4-10 kg | Reach 1200-1550 mm4.5/5 (3)

FANUC R-2000iC/165F

Payload 165kg | Reach 2655mm5/5 (2)

ABB IRB 2600

Payload 12-20 kg | Reach 1650-1850 mm4.9/5 (2)

KAWASAKI BX100L

Payload 100kg | Reach 2597mm4.7/5 (1)

ABB IRB 8700

Payload 1000kg | Reach 4200mm4.6/5 (1)

Estun Automation ER20-1200-MI

Payload 20kg | Reach 1200mm

Estun Automation ER8-720-MI

Payload 8kg | Reach 727mm

COMAU N-170

Payload 170kg | Reach 3000mm

FANUC LR Mate 200iD/7H

Payload 7kg | Reach 717mm4.4/5 (2)

COMAU NS-16-1.65

Payload 16kg | Reach 1650mm