Cobots are changing the game in industries like yours. These smart robots work alongside humans, making jobs easier, safer, and faster. No matter if you’re in a small workshop or a big factory, cobots can make a big difference. They’re not just about doing tasks automatically; they’re about improving teamwork between you and machines. If you’re in automotive, electronics, food and beverage, or other fields, cobots can be a real game-changer. Let’s explore how cobots are boosting efficiency in seven key industries, helping you stay ahead in a competitive market.

What is a Cobot?

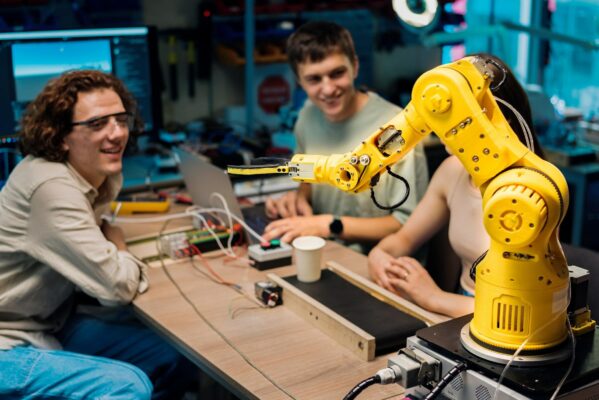

A cobot, or collaborative robot, is a type of robot designed to work alongside humans in a shared workspace. Unlike traditional robots that operate in isolation, cobots are built with safety and interaction in mind. They’re smart, adaptable, and can be programmed to perform a wide range of tasks – from assembly to painting, and even quality control.

With built-in sensors and safety features, cobots ensure a safe working environment for you and your team. They’re easy to set up and can be taught new tasks quickly, making them perfect for both small tasks and complex operations. Whether you’re looking to increase productivity, improve precision, or reduce the strain on your workers, cobots can help.

Think of cobots as your robotic teammates. They’re there to support you, taking on repetitive or physically demanding tasks, so you can focus on the work that requires a human touch.

To learn more in-depth about What is a Cobot, check this article out:

What is the Average Cost of a Cobot?

When considering adding a cobot to your team, it’s important to think about the investment involved. On average, a cobot costs around €27,000. While this might seem like a significant amount upfront, it’s crucial to consider the bigger picture. Cobots are incredibly flexible and can significantly reduce production costs over time. This means they can help your business stay competitive, even in markets where production costs are traditionally lower.

Investing in a cobot isn’t just about buying a piece of machinery; it’s about investing in efficiency, innovation, and the future of your company. By automating tasks, cobots free up your human workforce to focus on more complex and creative tasks, enhancing productivity and job satisfaction. Plus, the cost savings from increased efficiency and reduced errors can quickly offset the initial investment, making a cobot a wise choice for businesses looking to thrive in a competitive global market.

Industries Benefiting from Cobots:

1. Manufacturing:

Precision and flexibility are key to staying ahead, especially for manufacturing. These collaborative robots are transforming assembly lines, making them smarter and more efficient.

Cobots are designed to work alongside you, enhancing your production process. They are perfect for tasks that require a high degree of accuracy, such as screw driving, welding, and handling parts. With their precise movements, cobots ensure that each action is performed flawlessly, reducing the risk of errors that can lead to costly reworks.

But it’s not just about precision. Cobots bring incredible flexibility to your assembly line. They can easily switch between tasks with minimal downtime. Need to change from screw driving to welding? No problem. Cobots can adapt quickly, keeping your production line moving without missing a beat.

This adaptability makes cobots a valuable asset in manufacturing. They help you respond faster to market changes and customer demands, giving you a competitive edge. By integrating cobots into your assembly line, you’re not just improving efficiency; you’re setting your business up for success in a rapidly evolving industry.

2. Automotive:

Cobots play a crucial role in transforming production lines. Whether you’re assembling car components, tending to machines, or conducting quality inspections, cobots are your go-to for reliability and precision.

Cobots are masters of assembly, seamlessly integrating into your production line to fit parts together with impeccable accuracy. They’re also excellent at machine tending, loading and unloading components with a level of consistency humans can find challenging to maintain over long periods. But it’s not just about muscle; it’s about brains too. Cobots equipped with advanced vision systems are deployed in quality inspection, spotting defects with a level of detail that surpasses the human eye.

The benefits for you in the automotive sector are clear: enhanced safety and skyrocketing efficiency. Cobots work alongside your human team, handling dangerous tasks and reducing the risk of workplace accidents. Plus, their tireless work ethic means your production line keeps moving smoothly, minimizing downtime and boosting output.

Embracing cobots in your automotive manufacturing processes doesn’t just keep you competitive; it pushes you to the forefront of innovation, making your operation safer, faster, and smarter.

3. Electronics:

Cobots are your perfect partners, especially when it comes to assembling delicate components and carrying out precise soldering tasks. They bring a level of accuracy and consistency that’s hard to achieve manually, making them indispensable in your production line.

Cobots excel in handling the tiny, sensitive parts found in electronic devices. Their precision ensures that components are placed perfectly every time, reducing the risk of damage and waste. When it comes to soldering, cobots are equipped to perform highly detailed work with steady hands, ensuring strong and reliable connections without the variability that can come with human fatigue.

But it’s not just about doing tasks with precision; it’s also about keeping up with the pace of change. Electronics manufacturing is known for its rapid product evolutions, and cobots are remarkably adaptable to these changes. Programming cobots to handle new designs or tasks can be done swiftly, allowing you to maintain high-quality standards even as product specifications shift.

By integrating cobots into your electronics manufacturing process, you’re not just enhancing precision and efficiency; you’re also building a flexible production line capable of adapting to the future’s demands. This approach ensures that you stay at the cutting edge of technology, with the ability to quickly respond to market changes and maintain high-quality output.

4. Logistics:

In the logistics sector, time is of the essence, and efficiency is your top priority. Cobots are here to streamline your operations, making your processes faster, more accurate, and cost-effective. Whether it’s sorting packages, loading and unloading goods, or inventory management, cobots are your tireless workers, ready to boost productivity.

Cobots excel in repetitive tasks like sorting and moving items from one place to another. They can work round the clock, ensuring your packages are always where they need to be, without breaks or downtime. This constant motion keeps your supply chain moving smoothly, reducing bottlenecks and improving delivery times.

Loading and unloading goods is another area where cobots shine. They can be programmed to handle a wide range of item sizes and weights, doing the heavy lifting without the risk of injury. This not only makes your workplace safer but also increases the speed at which goods are processed.

Inventory management becomes more accurate with cobots. They can scan and track items, keeping your stock levels precise. This accuracy prevents overstocking or shortages, ensuring you have just what you need, when you need it.

5. Pharmaceutical:

In the pharmaceutical world, precision and cleanliness are everything. That’s where cobots come in. They help mix drugs, package them, and even run lab tests with a level of accuracy that’s hard to beat. This means better quality and consistency for the products you rely on.

Think about a cobot working in your lab. It handles sensitive materials perfectly, making fewer mistakes. This is crucial for making medicines that are safe and effective.

When it’s time to package these drugs, cobots are on it. They pack everything securely, making sure each package is just right. Plus, they label everything accurately, which is super important for safety.

Cobots are also stars in lab testing. They can do delicate tasks, like pipetting, with incredible precision. This helps get reliable test results. And because they’re designed for cleanrooms, they keep everything sterile, reducing contamination risks.

By bringing cobots into your operations, you’re not just making things faster. You’re making them safer and cleaner, too. Cobots are your behind-the-scenes heroes, ensuring every medicine meets the high standards you and your patients expect.

6. Food & Beverage:

In the food and beverage industry, efficiency, hygiene, and safety are really important. Cobots are stepping into this space to tranform how tasks like packaging, sorting, and palletizing are done, all while strictly adhering to the highest hygiene standards.

Imagine a production line where cobots handle your food packaging. They’re precise, never tire, and are easy to clean, ensuring that your products are handled in the most hygienic way possible. Cobots can also sort through products at lightning speed, picking out defects and ensuring only the best quality items make it to the next stage. When it comes to palletizing, these robotic helpers can organize and stack products with incredible efficiency, preparing them for shipment faster than ever.

But it’s not just about doing the work quickly; it’s about doing it smartly. Cobots are incredibly flexible, which is a huge advantage in an industry known for its seasonal peaks. They can be easily reprogrammed to handle different tasks or adjust to new product lines, ensuring your production can swiftly adapt to meet demand. This flexibility also extends to maintaining product safety, as cobots can be fitted with specialized tools and programmed to handle your products in a way that minimizes contamination risks.

7. Education:

In the education sector, cobots are not just tools; they’re interactive learning companions. Imagine having a cobot that helps with science experiments, demonstrating complex principles with ease and safety. This isn’t just about watching; it’s about engaging. You get to see theories in action, making learning more dynamic and memorable.

Cobots are also stepping in to assist in teaching coding and robotics. With their help, you’re not just learning from textbooks. You’re programming and interacting with robots directly. This hands-on experience is invaluable, providing a deep understanding of technology that’s shaping our future.

And it’s not just about technical skills. Cobots are helping with soft skills too. Working with them teaches teamwork, problem-solving, and creativity. These skills are essential, no matter what field you choose.

By integrating cobots into education, learning becomes more interactive, practical, and fun. They bring subjects to life, making complex concepts easier to grasp. Whether it’s science, technology, or essential life skills, cobots are enriching the learning experience, preparing you for a world where technology is everywhere.

Conclusion:

Cobots are changing the game across many industries, making work safer and tasks quicker. They’re not just robots; they’re your partners, helping in everything from building cars to packaging food and even testing drugs. Their ability to adapt and perform tasks with high precision makes them key players in fields like automotive, electronics, and pharmaceuticals. By choosing cobots, you’re choosing to stay ahead, ensuring your operations are efficient and cutting-edge. They’re about more than just automation; they’re about giving your business the boost it needs to lead in a competitive world. Cobots are here to help you excel, no matter your industry.