Franka Emika is well-known for its Panda cobot. It’s really popular with researchers and Ph.D. students. People who use it really like it, and it gets great reviews. Franka Emika used what they learned from making educational cobots to make this industrial one. They’re building on their earlier success.

“Franka Production 3, human-centered design with German engineering, is able to achieve high performance with their products, without compromising on the accessibility of the technology.”

– Franka Emika, 2022.

Why Industrial Cobots?

At a big event for industrial automation in Germany called Hannover Messe, Franka Emika showed off their new thing: the Production 3. What’s really cool is that they were the only all-German cobot brand there, competing with companies from all over the world.

In a surprising twist, they decided to focus on a new group of customers. They used what they knew from making educational cobots to create the amazing Production 3 (FP3).

Their press releases and videos clearly show that Franka Emika wants to change how robots are used. They want to make a platform that helps with making things in factories and other places. This could lead to more automation and a new way of doing manufacturing.

No doubt, the FP3 shows that Franka Emika is serious about helping the next generation of factory leaders.

Plus, the Production 3 has full TÜV certification, which means it meets important standards for being used in industries.

A Closer Look:

The Franka Production 3 is a robot made in Germany. It can sense force and is designed to make work more productive in different automation jobs. It uses the power of the internet and artificial intelligence to do tasks easily and without needing special knowledge about robots or hard-to-understand programming.

“Everyone can become a robot expert, turning their process expertise into robotic automation”

– Franka Emika, 2022.

Specifications:

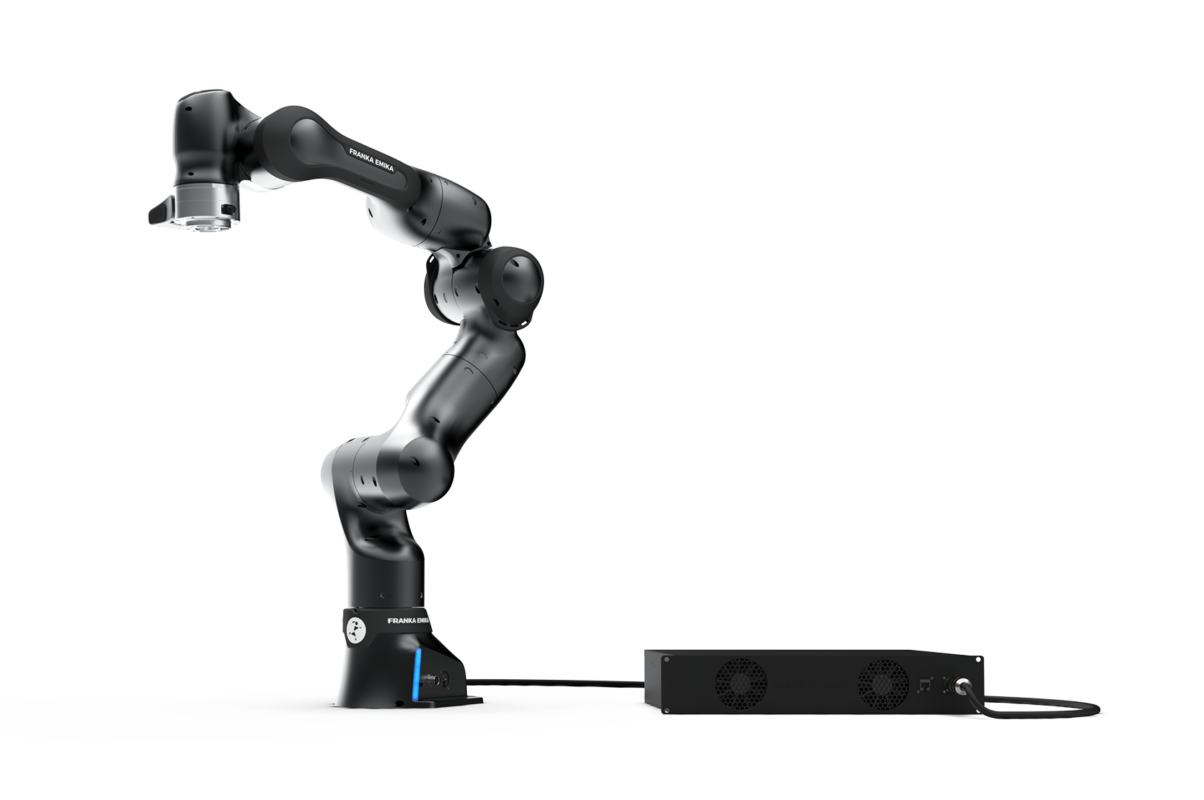

The Franka Production 3 has two main parts: the arm and the control unit. The arm is flexible and can move in seven different ways. It has sensors in each joint to feel how much force it uses. It can repeat its movements very accurately, only varying by about 0.1 millimeters, even when it moves quickly.

It can carry up to 3 kilograms of weight, reach out to 855 millimeters, and cover a wide workspace, about 94.5% of the area it works in. This makes the Franka Production 3 great at handling various tasks and being very adaptable.

Franka Emika Key Features:

1. Design:

The Franka Production 3 is designed like a human arm, making it perfect for delicate tasks that need precise force. It has over a hundred sensors, including special torque sensors on all seven joints. This robot is made to be flexible and dexterous, just like a human. You can easily set it up by guiding it with your hand. It’s simple to use. With a reach of 855mm, it can work effectively even when close to its base. Its seven degrees of movement allow it to perform complex tasks and work in tight spaces where other robots might struggle.

“This makes it the most sensitive lightweight robot on the market to date,”

– Dr. Patrick Pfaff, Chief Technology Officer of Franka Emika, 2022.

2. Accessibility:

- Franka Emika’s Production 3 is made for everyone. You don’t need to be a programmer to use it. It’s easy for anyone to run and program.

- You can start making money and getting more done quickly without spending a lot or needing special skills.

- You can control it from afar using the Pilot interface right on the robot arm. It’s designed to be simple to use.

3. Reduced Downtime:

- You don’t need a team of robot experts to set up and run this. It’s easy to use and doesn’t require much training. You can start using it within 30 minutes.

- You can quickly change tasks as your factory’s needs change by using App Workflows. It’s a flexible way to keep up with a fast-paced factory.

4. Enhanced Safety:

The system uses sensors, smart algorithms, and internal models to quickly detect and stop collisions. It happens in milliseconds to keep accidents from happening.

To learn more Franka Emica Production 3.