Looking for the perfect robot to upgrade your factory in 2025? You’re in the right place. Industrial robots are changing the game by making your production faster, more precise, and reliable. Whether you need a robot for heavy lifting, precise assembly, or nonstop operation, the right choice can transform your manufacturing line.

This guide highlights the top 5 industrial robots of 2025 to help you find the best fit for your needs. From boosting efficiency to cutting down errors, these robots are built to tackle your toughest challenges. Let’s find the perfect robot to power your factory forward!

What is an Industrial (Articulated) Robot?

An industrial articulated robot is like a high-powered, flexible robot arm designed for factory work. With multiple joints that bend and rotate, it moves like a human arm but works faster, smarter, and with perfect accuracy.

Why Should You Care?

If you run a factory, this robot works non-stop, handling repetitive tasks without breaks, mistakes, or slowdowns. Imagine producing more, faster, while reducing errors—these robots make that possible.

To learn more about Industrial Robots, check out this article:

What Can It Do?

Articulated robots are incredibly versatile. You can program them to:

- Assemble parts quickly and precisely.

- Weld and cut materials with accuracy.

- Paint or coat products flawlessly.

Pick, pack, and move heavy or delicate items with ease.

*These are based on real user reviews.*

Top 5 Industrial Robots of 2025:

1. Stäubli TX2 Series:

Qviro Score: 4.3/6 Reviews

Looking to boost your manufacturing line with an industrial robot? Stäubli’s TX2 Series is your answer. These robots are great for their precision and flexibility.

The TX2-40 is a game-changer. With a 6-axis design, it can handle a 2 kg payload and reach up to 515 mm. It’s safe for various industries, thanks to its NSF H1 compatibility and SIL3-PLe safety rating. Perfect for precise, delicate tasks.

Need something stronger? The TX2-90 has you covered with a 14 kg payload and 1000 mm reach. For tasks that need a bit more reach, the TX2-90L stretches to 1200 mm with a 12 kg payload. And for the longest reach without a heavy load, the TX2-90XL reaches 1450 mm with a 7 kg payload.

For the heavy lifting, turn to the TX2-140. It boasts a 40 kg payload and 1510 mm reach, handling hefty tasks with ease.

The TX2 Series stands out for blending safety, efficiency, and versatility. Whatever your need, there’s a TX2 robot ready to boost your production line.

Here are some things that users have said:

2. ABB IRB Series:

Looking for robots that boost your line’s efficiency? ABB’s got you covered. With the IRB 6700, IRB 4600, and IRB 1600, you’re looking at consistent performance and versatility.

The IRB 6700, rated 4.6/9 reviews, is a powerhouse in the 150-300 kg class. It cuts ownership costs by 20% through its tough design and less frequent need for maintenance. It’s perfect if you’re aiming for high performance without the extra costs.

This is what some users are saying:

Switch to the IRB 4600, scoring a 4.8/3 reviews, for unmatched efficiency in general-purpose applications. With its ability to shorten cycle times by up to 25% and a payload capacity of 20-60 kg, it’s designed to enhance your productivity. Its compact size allows for high-density cell creation, making it a smart choice for maximizing output.

Then there’s the IRB 1600, scoring 4.5/3 reviews. It’s the best for 10kg loads, delivering quick cycles and top-quality work. Even in harsh conditions, it keeps going 24/7, thanks to ABB’s smart motion controls and flexible setup.

Whether you’re lifting heavy, welding, or needing fast, reliable cycles, ABB’s robots are here to step up your game. Let’s pick the perfect one for your needs.

3. Yaskawa:

Dive into Yaskawa’s world of automation excellence with their SP80 robot and GP25 robot. Each brings something unique to your production line, enhancing efficiency and precision.

Starting with the SP80, rated 4.7/1 review, it’s the go-to for spot welding and handling tasks. Despite being the smallest in its series, it packs a punch with an 80 kg payload and a 2236 mm reach. Its design is sleek, fitting into tight spaces while covering a large work area. Powered by the YRC1000 controller and Sigma-7 servo technology, it promises dynamic performance, energy savings, and impressive cycle times.

Secondly, the GP25, scoring 4.9 from 3 reviews, is your versatile ally with a 25 kg payload and 1730 mm reach. It shines in accuracy with a repeatability of +/- 0.02 mm, perfect for tasks needing the utmost precision.

Here’s what some users have said:

Whether you’re into welding, need powerful control over multiple robots, or demand precision in handling, Yaskawa’s lineup has your back. Let’s pick the best fit to turbocharge your production with Yaskawa’s automation excellence.

4. KUKA:

Explore KUKA’s robotic solutions, designed for adaptability and efficiency in various industrial applications. Each model from the KR series brings its unique strengths, catering to different operational needs with precision and agility.

KUKA KR 150 R3100-2: With a rating of 4.7/1, this robot is engineered for tasks demanding dynamic performance. It’s designed for a standard payload of 150 kg but can handle up to 220 kg under certain conditions. Its 3100 mm reach extends its versatility across multiple tasks. For specific applications, it’s essential to verify load conditions using KUKA’s specialized software, ensuring optimal performance tailored to your needs.

KUKA KR 240 R3200 PA: Rated 5.0/1, this 5-axis powerhouse is known for its speed and the ability to accelerate optimally, even under full load. It boasts a 3195 mm reach and a 240 kg payload capacity, making it perfect for material handling, order picking, palletizing, and part transfers. It’s designed not just for performance but also for cost efficiency and enhanced product quality, thanks to its compatibility with the KR C4 controller.

KUKA KR 60 L30 KS: Another top scorer with a 5.0/1 rating, this 6-axis robot is a paragon of precision and reliability. With a 150 kg payload and a 3095 mm reach, coupled with a remarkable repeatability of 0.06 mm, it meets the demands of applications where accuracy is paramount.

Here’s what a user said:

Whether your operations require handling heavy loads with dynamic performance, speed and acceleration for material handling, or precision for detailed tasks, KUKA’s KR series offers a robotic solution tailored to enhance your production line. Choose the right model to unlock new levels of efficiency and quality in your operations.

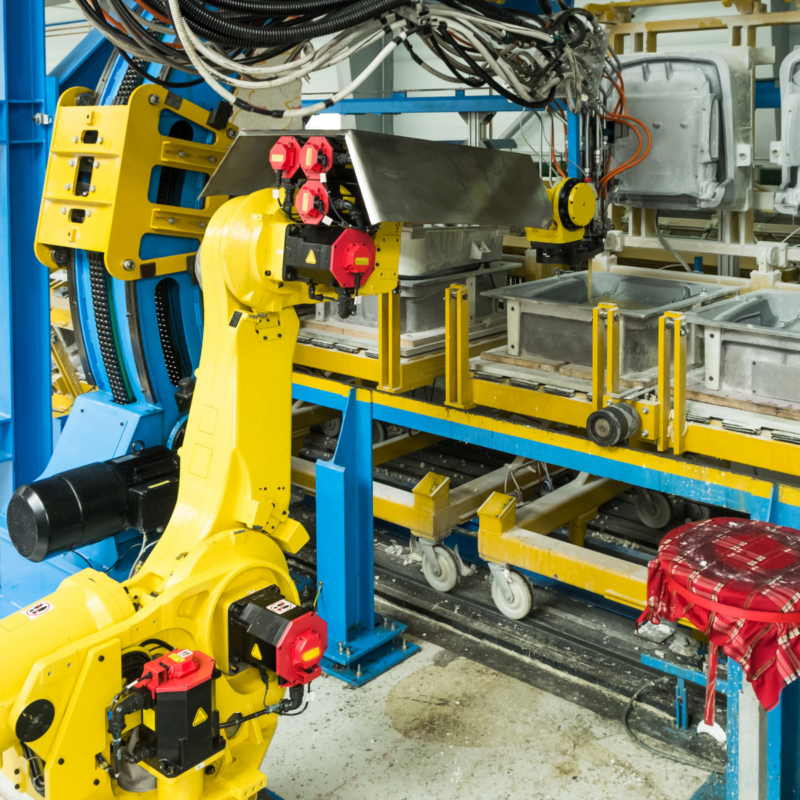

5. FANUC:

Discover FANUC’s groundbreaking robots, the M-20iB/25 and R-2000iC/165F. These robots are game-changers in the world of automation, designed to make your production line more efficient and adaptable.

FANUC M-20iB/25 has a 4.9 rating/1. It’s a trailblazer in the M-20iB series, built to move quickly and boost your output. Thanks to its lightweight design and advanced technology, it speeds up cycles. It’s also tough, ready to work in any condition, even the messy ones, with a solid build that keeps out dirt and water. It can lift 25kg and reach up to 1853mm, making it perfect for a variety of tasks.

FANUC R-2000iC/165F scores 5.0/2. This versatile robot can do it all, with a design that’s ideal for fast and efficient spot welding. It’s slim enough to fit into tight spaces and work closely with other robots without any issues. With the ability to lift 165kg and a reach of 2655mm, it can handle nearly any job you throw at it.

Here’s what a user said about it:

Both these FANUC robots are designed with your needs in mind. They’re fast, flexible, and built to last, ready to tackle challenges and improve your production line.

Whether you need speed, the ability to work in harsh conditions, or versatility, FANUC offers solutions that exceed expectations. Choosing FANUC means upgrading your manufacturing process with top-notch technology, paving the way for success and growth. Step into the future of manufacturing with FANUC’s robots and watch your productivity soar.

Conclusion:

Industrial robots make work faster, better, and more reliable. These robots do the boring or tough tasks, so people can focus on the more interesting parts of the job. They’re perfect for precise work like putting things together or painting, working non-stop to make sure everything runs smoothly and costs stay down. Getting a robot for your team isn’t just about keeping up with tech trends; it’s a smart move to stay ahead in a tough market. They can be a big help in making your production line more efficient and improving the quality of what you make.

Do you want to compare different Industrial Robots?