Delfoi ARC Specifications

Ranked Nr. 42 of 85 Robot Software

Delfoi ARC is a fast and user-friendly offline programming software for all major robot brands.

Based on selected parameters and features, the program can effectively utilise the features of the 3D CAD model and the internal WPS (Welding Procedure Specification) database of the software.

- Fast and easy: semi-automatic programming with user friendly user interface

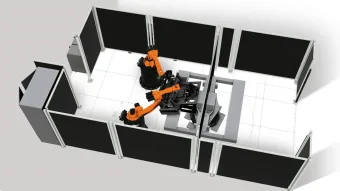

- Multi-Robot System: supports programming of multiple synchronously co-working robots

- Jigless welding: a robot as the part positioner while another robot is welding

- High quality programs: integrated quality control and WPS (Welding Procedure Specification)

- Accurate tool paths: advanced calibration tools and trajectory management

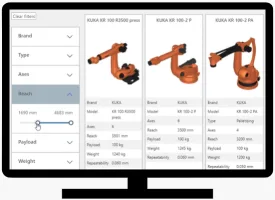

- Generic: supports ABB, Fanuc, KUKA, Yaskawa, Motoman, Kawasaki, Panasonic, IGM, CLOOS, Reis etc.

Process features

- ‘Straight weld’ wizard

- ‘Curved weld’ wizard

- Seam searching in (1D, 2D or 3D), and auto-search

- Multi-pass welding and automatic generation of passes

- Stitch welding

- Sharp corner welding

- Copying and mirroring of welds

- Management of welding process settings and features (e.g. welding voltages, welding speeds and seam tracking)

- WPS welding parameter database

- Robot configuration management

- Tool change management

- Automated, unrestricted calculation/management of all external robot axes (e.g. gantry positioners, linear tracks and multi-axis workpiece positioners)

- Easy and fast fine adjustment of all weld paths and the robots via and moving points

- Fast validation and correction of paths

- Versatile calibration tools to ensure extreme precision in the programming of modelled cells

Advanced features

Solver Bundle is combined of advanced, automatic path planning solvers, that solve trouble-free tool paths, like weld paths, via paths and search paths. The solver bundle is included in Delfoi Auto ARC software.

| Software type |

|

| Type |

|

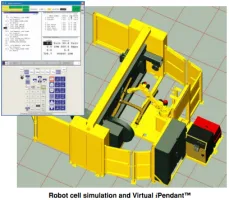

| Extra info | Simulation: A wide-ranging component library for use in cell layout-modelling – over 2 000 default robot and workpiece positioner models and dozens of smart, parametric components, such as conveyor belts, light curtains and safety barriers / Automatic detection of collisions and “near-miss” incidents with visual feedback / Cell layout planning and fast positioning of components within a cell / Review of the robot’s working envelope / Automatic detection of violations of axis limits with visual feedback / Automatic detection of robot singularity issues / Fast and effective simulation of created welding programs, either in real time or set to a variable speed / Option to save a simulated program in either 3D-PDF or AVI format and easy sharing of files / |