Delfoi SPOT Specifications

Ranked Nr. 49 of 85 Robot Software

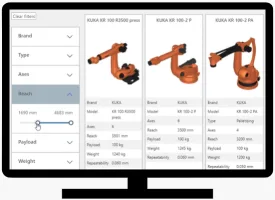

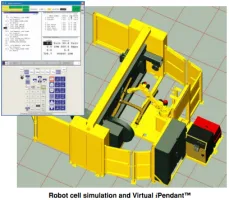

Delfoi SPOT is a fast, user-friendly, parametric and feature based offline programming software. The software can effectively utilise the features of a 3D CAD model. The necessary tools can be created in the software’s internal tool library, where the geometrical information is generated automatically. It is possible to create programs quickly and without the need for trial and error, and regardless of the robot brand.

Process features

- Import spot data from external source

- Manual spot picking

- Easy modification

- Robot synchronization

- IO-signals

- Collision detection; see advanced features

- Automatic path checking

- Management of robot tool changes

- Versatile calibration tools to ensure extreme accuracy for tool paths

Advanced features

- Automatic spot-welding path solver for collision free tool paths

- SPOT Importer – Import spot weld positions from external file: CSV, XML, Custom

| Software type |

|

| Type |

|

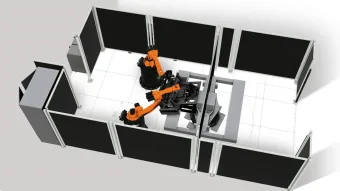

| Extra info | Simulation: A wide-ranging component library for use in cell layout-modelling – over 1 000 default robot and positioner models and dozens of smart, parametric components, such as conveyor belts, light cells and safety barriers / Automatic detection of collisions and “near-miss” incidents with visual feedback / Cell layout planning and easy positioning of components within a cell / Review of the robot’s range of movement / Automatic detection of violations of axis limits with visual feedback / Automatic detection of singularity points / Fast and effective simulation of spot-welding programs, either in real time or set to a variable speed / Option to save the simulated programme in either 3D-PDF or AVI format and easily share the file with others |