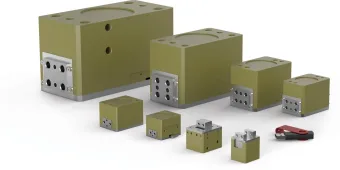

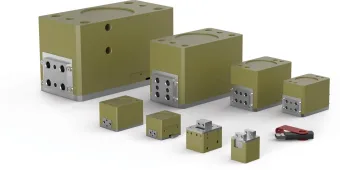

DESTACO CAM LEVER PARALLEL GRIPPERS FOR PNEUMATIC & HYDRAULIC OPERATIONS – REP-2 SERIES Specifications

Ranked Nr. 378 of 235 Grippers

Designed for assembly manufacturing cells, packaging applications, and general purpose gripping. Compact cam lever designed, general purpose gripper. Pneumatic and hydraulic operation options. Spring assist option for part retention in case of air pressure loss. Standard and extended stroke option available. Shielded design for harsh environments. Magneto-resistive and inductive sensing.

Choose your model:

MULTI-PURPOSE, POWERFUL PARALLEL GRIPPERS FOR HEAVY PARTS – RTH SERIES

Parallel

WIDE BODY, PARALLEL GRIPPERS FOR HARSH ENVIRONMENTS – RPW SERIES

Parallel

SEALED, PARALLEL GRIPPERS FOR AUTOMOTIVE ASSEMBLY & PACKAGING – RPS SERIES

Parallel

LONG STROKE, PARALLEL GRIPPERS FOR FOUNDRIES & HEAVY PARTS HANDLING – RPR SERIES

Parallel

MINIATURE, PARALLEL GRIPPERS FOR SMALL PART GRIPPING – RPM|RPMC SERIES

Parallel

LONG, PRECISE PARALLEL GRIPPERS FOR CLEAN ROOMS & HARSH ENVIRONMENTS – RPL|RPLC SERIES

Parallel

SELF-CENTERING PARALLEL GRIPPERS HEAVY PARTS & LATHE APPLICATIONS – RPC SERIES

Parallel

PARALLEL GRIPPERS – RPB SERIES

Parallel

SEALED PARALLEL GRIPPERS FOR AUTOMOTIVE ASSEMBLY APPLICATIONS – RP-5-10 SERIES

Parallel

SEALED PARALLEL GRIPPERS FOR AUTOMOTIVE ASSEMBLY APPLICATIONS – RP-11-19 SERIES

Parallel

PRECISION PARALLEL GRIPPERS FOR DELICATE PART HANDLING – RP-P SERIES

Parallel

MULTIPURPOSE PARALLEL GRIPPERS FOR PICK-AND-PLACE & PART FEED APPLICATIONS – REP-3 SERIES

Parallel

CAM LEVER PARALLEL GRIPPERS FOR PNEUMATIC & HYDRAULIC OPERATIONS – REP-2 SERIES

Parallel

RUGGED, MULTI-PURPOSE PARALLEL GRIPPERS FOR HEAVY PARTS – RDH SERIES

Parallel

MULTIPURPOSE, ROBUST PARALLEL GRIPPERS WITH HIGH REPEATABILITY – PPC SERIES

Parallel

LONG FINGER PARALLEL GRIPPERS FOR HARSH ENVIRONMENTS – DPW SERIES

Parallel

PRECISION, LONG FINGER PARALLEL GRIPPERS – DPP SERIES

Parallel

LONG STROKE, HIGH GRIP FORCE PARALLEL GRIPPERS FOR PICK-AND-PLACE – DPL SERIES

Parallel

GENERAL PURPOSE MODULAR, PARALLEL GRIPPERS WITH MULTI-POSITION SENSING – DPG SERIES

Parallel

COMPACT, ROBUST PARALLEL GRIPPERS FOR CONFINED SPACES – DPDS SERIES

Parallel

GENERAL PURPOSE, PARALLEL MODULAR GRIPPERS FOR HIGH IMPACT APPLICATIONS – DPDL SERIES

Parallel

PARALLEL OR EXTENDED FINGER GRIPPERS FOR OEM PICK-AND-PLACE APPLICATIONS – CP SERIES

Parallel

PARALLEL GRIPPERS FOR HYDRAULIC POWERED & WELDING APPLICATIONS – 3P SERIES

Parallel

PARALLEL GRIPPERS FOR HYDRAULIC POWERED & WELDING APPLICATIONS – 2P SERIES

Parallel

GRIPPING SOLUTIONS FOR OEM APPLICATIONS - G110 & G120 SERIES

Parallel

COMPACT, ELECTRIC 2-JAW PARALLEL GRIPPERS FOR ENGINEERING & MANUFACTURING – RPE SERIES

Parallel

DPE Series Electric Parallel Grippers Electric, 2-Jaw Parallel Grippers Tested for 20+ Million Cycles – DPE Series

Parallel

2-JAW ANGULAR GRIPPERS WITH CYLINDRICAL SPRING ASSIST - RUA

Angular

ANGULAR GRIPPERS WITH TOGGLE LOCKING MECHANISM - RA

Angular

CAM DRIVEN ANGULAR GRIPPERS - RA

Angular

2-JAW ANGULAR GRIPPERS FOR FOOD HANDLING - FUA

Angular

2-JAW ANGULAR GRIPPERS – DCT|CT SERIES

Angular

| Operation type |

|

| Extra info | Fail-safe grippers / lightweight / Originator of the double-wedge design for long-life, robust grippers / The DirectConnect™ feature allows for a complete multi-axis pick & place solution without the need for transition plates / Low break-away precision grippers for picking up fragile precision parts with high repeatability / Available in a wide range of sizes and configurations / |

CAM LEVER PARALLEL GRIPPERS FOR PNEUMATIC & HYDRAULIC OPERATIONS – REP-2 SERIES Downloads

REP2 Maintenance 3827

You need to

register

to download this file.