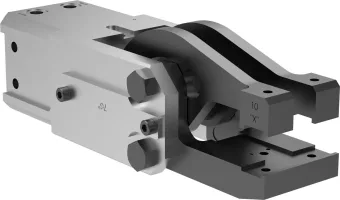

DESTACO COMPACT, ELECTRIC 2-JAW PARALLEL GRIPPERS FOR ENGINEERING & MANUFACTURING – RPE SERIES Specifications

Ranked Nr. 378 of 235 Grippers

These electric parallel grippers have a spring closed feature that allows for full grip force during power off conditions. They require simple 24VDC pulsed signal, without programmable or expensive controller required. Adjustable inductive proximity sensors are also available. Easily integrated into current engineering and manufacturing processes. Their compact design allows for gripping small parts in small spaces. Preloaded “Dual-V” roller bearings eliminate sideplay for excellent part position repeatability. Low friction mechanism allows for repeatable gripping forces for holding delicate parts. Gripforce is constant throughout stroke. A corrosion resistant shield protects the drive and bearing mechanism. All internal components are lubricated with Krytox™grease. All moving components are located within the corrosion resistant cover.

| Energy source |

|

| Number of fingers |

|

| Operation type |

|

| Extra info | Simple and fast installation, no software required / Energy efficient reducing operation costs / Easier to operate and control than pneumatic grippers / The DPE-200-25 is suitable for a Class 6 environment as per ISO 14644-1. Certificate of Compliance / The DPE-400 is suitable for a Class 5 environment as per ISO 14644-1. Certificate of Compliance / Zero maintenance for maximum machine uptime / No valves, tubing, compressor, or filters required / The DirectConnect™ feature allows direct mounting to other DESTACO Robohand rotary and slide products. |