- Turnkey Robot Solutions

- HAHN Robotics

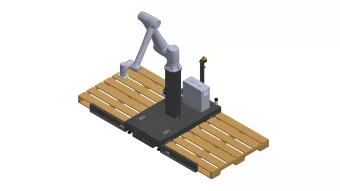

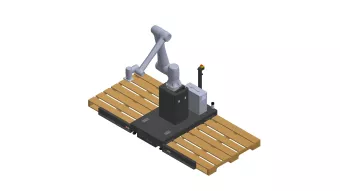

- Palletizing Kit

- Specifications

HAHN Robotics Palletizing Kit Specifications

Ranked Nr. 58 of 61 Turnkey Robot Solutions

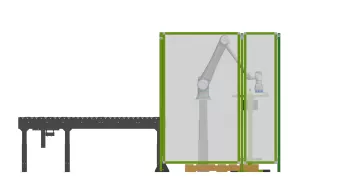

The Palletizing Kit from HAHN Robotics revolutionizes the palletizing of products weighing up to 17 kg using collaborative robotics. It is immediately and flexibly deployable, space-saving and officially approved for operation without external protective equipment. With an intuitive, fully integrated interface, even complex, new patterns can be configured in minutes without prior knowledge – ideal for a changing product range. At the same time, two storage bays, also suitable for oversized pallets, ensure a continuous material flow. The connection to intralogistics is made by means of conveyor technology and preconfigured interfaces to driverless transport systems.

Palletizing Kit Downloads

FACTSHEET PALLETIZING KIT 07 22 DE 5

You need to

register

to download this file.

Palletizing Kit Alternatives

See all 85 Turnkey Robot Solutions

Qviro Dobot Static Palletizer CR20A

No reviews yet.

Qviro Dobot Palletizer with lift column CR20A

No reviews yet.

Qviro Palletizer Dobot CR20A + Lift Column

No reviews yet.

Impaqt Robotics cobotizur

3.5/5 (1)

Unchained Robotics MalocherBot Palletizing S

No reviews yet.

SKDK APC-15 / APC-35

No reviews yet.

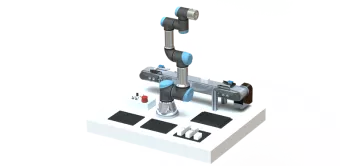

UNIVERSAL ROBOTS Collaborative Robotics Training Kit

No reviews yet.

Unchained Robotics MalocherBot Palletizing

No reviews yet.

SKDK APCX-10

No reviews yet.

SKDK APCX-20

No reviews yet.

Onexia PalletizUR

No reviews yet.