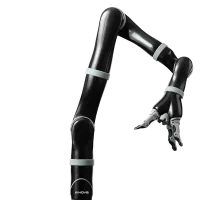

KINOVA Gen2 (7DoF) Alternatives & Competitors

Ranked Nr. 17 of 207 Cobots

Top 10 Gen2 (7DoF) Alternatives

- Elephant Robotics mechArm 270-Pi

- KINOVA Gen2 (6DoF)

- KINOVA Gen3 (7DoF)

- DOOSAN M1013

- KINOVA Gen3 Lite

- KINOVA Gen3 (6DoF)

- HITBOT Z-Arm 1832

- HITBOT Z-Arm 2442

- DOOSAN H2515

- LIFE ROBOTICS Unknown

- TATA GEN-I TR05-2

Elephant Robotics mechArm 270-Pi

Payload 0.25kg | Reach 270mmThe MechArm 270-Pi is a six-axis collaborative robotic arm that is designed to be compact and powered by a Raspberry Pi. This robotic arm is a DIY kit that allows users to build their own robotic arm and program it to perform various tasks.

The MechArm 270-Pi is one of the most compact six-axis collaborative robotic arms on the market. It has a reach of 270mm and a payload capacity of 0.25kgs, which makes it ideal for small-scale automation tasks. The arm is designed to be collaborative, which means it can work safely alongside humans without causing any harm.

The robotic arm is powered by a Raspberry Pi, which is a popular single-board computer that can be programmed using a variety of programming languages. The Raspberry Pi provides a user-friendly interface for programming the arm, and it also allows the arm to be integrated with other devices and systems.

The MechArm 270-Pi is a DIY kit, which means that users need to assemble the arm themselves. The kit includes all the necessary components, including the motors, the controller, and the Raspberry Pi. The assembly process is straightforward and can be completed in a few hours.

Once the arm is assembled, users can program it to perform various tasks using Python or other programming languages. The robotic arm can be used for a wide range of applications, such as pick-and-place tasks, machine tending, and quality control.

KINOVA Gen2 (6DoF)

Payload 2.6kg | Reach 985mmThe Kinova Gen2 (6DoF) is an exceptional robotic arm renowned for its portability, safety, and efficiency. With its ability to manipulate objects in any three-dimensional workspace, the Gen2 stands out as a versatile option for industrial automation. Its standout feature lies in its ultra-lightweight design, making it highly portable and easy to move between different workstations. This remarkable portability allows it to be utilized in various industries and applications, offering unmatched flexibility.

Another key highlight of the Kinova Gen2 is its low power consumption, making it an energy-efficient solution for automation tasks. This feature not only saves costs but also promotes sustainable practices in manufacturing and other industries. Additionally, the Gen2 boasts an excellent payload-to-weight ratio, enabling it to handle relatively heavy objects despite its compact and lightweight structure. This combination of high payload capacity and portability makes it an attractive choice for applications that require both strength and mobility.

The Gen2 is designed with a strong focus on safety and human-robot interaction. It is engineered to operate safely around people and aims to augment human capabilities in various environments. This emphasis on collaboration ensures that the user remains in control of the technology, with the robot complementing their skills rather than replacing them. As a result, the Gen2 empowers users to achieve tasks more efficiently and effectively, leading to extraordinary results.

In addition to its standout features, the Kinova Gen2 offers lesser-known specialized specifications that further enhance its appeal for industrial automation. Notably, it has a tolerance for extreme temperatures, enabling it to operate in challenging environments with wide temperature fluctuations. This capability expands its use cases in industries where temperature control is critical. Furthermore, the Gen2 is compatible with both the Robot Operating System (ROS) and Kinova's proprietary software, providing users with flexibility and ease of integration into existing systems.

KINOVA Gen3 (7DoF)

Payload 4kg | Reach 902mmThe Kinova Gen3 (7DoF) is an ultra-lightweight robotic arm, designed for exceptional portability and rapid setup time. With its efficiency and versatility, the robot can be seamlessly moved between research teams, applications, projects, and environments, requiring less than 30 minutes for setup. This flexibility opens up a world of possibilities, making it a top choice for hundreds of universities, startups, and corporations embarking on their innovation journey.

One of the standout features of the Gen3 is its exceptional control capabilities. It offers 1 kHz closed-loop control at a low level, ensuring precise and smooth movements for various tasks. The robot's joints provide infinite rotation, further enhancing its flexibility and adaptability for a wide range of applications.

The Gen3 is equipped with smart actuators that feature integrated torque sensors. This advanced technology allows for precise force control and interaction with the environment, enhancing the robot's ability to handle delicate and intricate tasks with accuracy.

For users looking to incorporate vision capabilities, the Gen3 offers an optional 2D/3D vision module. This module enables the robot to perceive its surroundings and interact with objects in a more intelligent and dynamic manner.

Another key advantage of the Gen3 is its seamless integration with various software systems and programming environments. It supports the Kinova Kortex™ API software, which facilitates easy communication and coordination with other technologies. Moreover, users have the flexibility to program the robot using their preferred tools and languages, including C++, Python, MATLAB hardware support package, and ROS 2 package. This adaptability streamlines the integration process and allows users to work with the robot more efficiently.

Additionally, the Gen3 is compatible with Gazebo and MoveIt simulation environments, which further simplifies development, testing, and optimization of robotic applications. These simulation environments enable users to visualize and validate their ideas before implementation, saving time and resources.

DOOSAN M1013

Payload 10kg | Reach 1300mmDoosan's M1013 cobot is a highly efficient and versatile robotic arm that can perform a wide range of industrial automation tasks. Its compact and lightweight design makes it easy to install and integrate into any workspace, while its advanced sensor technology ensures precision and accuracy in all operations.

The M1013 boasts an impressive load capacity of up to 13 kg and a maximum reach of 1013 mm, making it ideal for a range of applications such as packaging, assembly, and material handling. It also features six torque sensors in each joint, providing advanced force control and collision sensitivity for maximum safety in operation.

The M-SERIES cobots are compatible with a range of software systems, including Doosan's own proprietary control software, which allows for easy programming and customization of tasks. Additionally, the M1013 is capable of operating in extreme temperatures, making it a reliable choice for industrial automation in a variety of environments.

Another standout feature of the M1013 is its ease of use and intuitive design, making it accessible for users with varying levels of technical expertise. Its modular design also allows for easy maintenance and repair, ensuring maximum uptime and productivity.

KINOVA Gen3 Lite

Payload 0.5kg | Reach 760mmThe Kinova Gen3 Lite is the newest and most compact member of the Kinova ultra-lightweight robot series, offering a cost-efficient option for professional-grade robotic arms to perform light manipulation tasks. It is particularly well-suited for professional academic-level education needs.

One of the standout features of the Gen3 Lite is its ultra-lightweight design, making it highly portable and power-efficient. This characteristic makes it an ideal choice for mobile applications, where agility and efficiency are essential.

The Gen3 Lite runs on the powerful and robust Kinova® Kortex™ API software, enabling seamless programming sharing and collaboration with other Gen3 Lite or Gen3 units. This compatibility with the Kortex API software enhances its versatility and opens up possibilities for coordinated tasks in various robotic setups.

This compact professional robot sets a new standard in adaptability, catering to users of all expertise levels. Whether you require simple grasping tasks or more complex manipulation applications in MATLAB, ROS 2, C++, or Python, the Gen3 Lite can be easily programmed and controlled.

The robot's actuators feature embedded controllers, which offer efficient and transparent operation. It also provides both high-level and low-level control, allowing for precision in various applications. The Gen3 Lite's low-level closed-loop control operates at 1 kHz, ensuring smooth and accurate movements.

Setting up the Gen3 Lite is hassle-free, taking less than 10 minutes to get started. It offers simple connectivity options through USB, Ethernet, and RNDIS (Remote Network Driver Interface Specification). Moreover, users can connect to the Kinova Web App from any desktop, laptop, or mobile device, streamlining the programming and control process.

In addition to its key features, the Gen3 Lite includes lesser-known specifications that make it an attractive option for industrial automation. For instance, it has a high tolerance for extreme temperatures, allowing it to function reliably in challenging environmental conditions. This resilience makes it suitable for a broader range of applications, particularly in industries with varying temperature demands.

KINOVA Gen3 (6DoF)

Payload 4kg | Reach 891mmThe Kinova Gen3 is an ultra-lightweight 6DoF robotic arm designed for quick setup and portability. It features 1 kHz closed-loop control for precise movements, infinite joint rotation for maximum flexibility, and smart actuators with torque sensors for better interaction with its environment.

The Gen3 offers a 2D/3D vision module for enhanced perception and integrates easily with other technologies through the Kinova Kortex API software. It supports various programming environments like MATLAB, ROS 2, C++, and Python, as well as simulation in Gazebo and MoveIt.

Its tolerance for extreme temperatures makes it ideal for industrial automation in challenging environments. Overall, the Kinova Gen3 combines efficiency, versatility, and durability, making it a trusted choice for research and industry applications.

HITBOT Z-Arm 1832

Payload 1kgHITBOT Z-Arm 1832, is a cutting-edge robotic arm designed for precision, flexibility, and collaboration. This robotic arm has a compact design, measuring only 500mm in height and weighing 11KG, making it easy to deploy in various application scenarios.

The HITBOT Z-Arm 1832 is a 4-axis collaborative robotic arm with a maximum payload of 1KG and a rated payload of 0.5KG. It has a linear velocity of 1017mm/s and a repeatability of ±0.02mm. The J1 and J2 axes have an arm reach of 160mm and a rotation range of ±90° and ±143°, respectively. The Z-axis has a reach of 180mm, while the R-axis has a reach of ±1080°. This range of motion enables the robotic arm to perform various tasks with great precision.

One of the standout features of the HITBOT Z-Arm 1832 is its ease of use. It is designed to be simple but versatile, with a handheld teaching programming system that makes it easy to program and use. Additionally, it supports SDK secondary development, allowing users to customize its functionality according to their needs.

Another essential feature of the HITBOT Z-Arm 1832 is its collaborative and safe design. It supports collision detection, which ensures smart human-machine collaboration and prevents accidental collisions. This makes it safe to use in various settings, including those where humans are present.

The HITBOT Z-Arm 1832 is compatible with a range of HITBOT grippers, including the Z-EFG-8S, Z-EFG-12, Z-EFG-20, and Z-EFG-20S. It also has I/O ports for digital input and output (isolated) and customizable Z-axis height, with drag-to-teach capabilities.

In conclusion, the Hatbox's 832 Collaborative Robotic Arm, the HITBOT Z-Arm 1832, is a top-of-the-line robotic arm that is both compact and precise. Its flexibility, simplicity, and versatility make it an ideal choice for various applications, while its collaborative and safe design ensures that it can be used safely in various settings.

HITBOT Z-Arm 2442

Payload 3kgThe Hitbot Z-Arm 2442 is a collaborative robotic arm designed for various industrial applications. This lightweight robotic arm weighs only 19kg and has a compact design, making it easy to install and use in confined spaces. The robot has a built-in motion controller, with 24 I/O ports for extensibility and adding one more arm.

The robot has four axes, with a maximum payload of 3kg and a rated payload of 2kg. The robot arm has a reach of 220mm for the J1 axis, 200mm for the J2 axis, and 240mm for the Z-axis. The rotation range for the J1 axis is ±90°, for the J2 axis is ±164°, and for the R-axis (optional) is ±1080°. The maximum average linear velocity of the robot arm is 1255.45mm/s (with a 1.5kg payload) and 1023.79mm/s (with a 2kg payload). The repeatability of the robot arm is ±0.03mm.

The robot arm supports HITBOT grippers such as Z-EFG-8S, Z-EFG-12, Z-EFG-20, Z-EFG-20S, Z-EFG-30, and Z-EFG-50. Additionally, the robot arm has optional accessories such as grippers, a 5th axis, a 485 board, and a 3D printing kit. The robot arm has a customizable Z-axis height ranging from 0.1-1 meter and supports drag-to-teach programming.

The robot arm has a voltage of 220V/110V 50-60Hz DC24V and power of 500W. The robot arm communicates through Ethernet and has a working temperature range of 0-55℃ with RH85 humidity. The robot arm has digital input (isolated) with 9+3 arm extensibility and digital output (isolated) with 9+3 extensibility for one more arm. The robot arm has collision detection technology, making it safe to operate in human-machine collaboration scenarios.

Overall, the Hitbot Z-Arm 2442 is a high-performance and versatile robotic arm that can be used in various industrial applications, including pick-and-place, assembly, and packaging. With its lightweight and compact design, customizable height, and extensibility, it is an excellent choice for industries looking for cost-effective and efficient automation solutions.

DOOSAN H2515

Payload 25kg | Reach 1500mmDoosan's H2515 cobot is a state-of-the-art automation solution that offers unparalleled power and precision. With a 1,700 mm reach and a payload of up to 25 kg, it is one of the strongest and most capable cobots available. Despite its impressive capabilities, the H2515 is incredibly lightweight, weighing only 75 kg, making it much easier to transport and install than other robots with similar payload capacities.

The H2515, along with the H2017 model, is part of Doosan's H-SERIES, which is designed for heavy-duty applications such as logistics and automotive manufacturing. Equipped with six high-tech torque sensors in all six axes, the H2515 provides the dexterity and flexibility needed to handle complex tasks with precision and accuracy.

In addition to its impressive payload capacity and torque sensors, the H2515 is also designed to operate in extreme temperatures, making it a reliable option for a range of industrial settings. Its compatibility with various software systems and programming languages makes it easy to integrate into existing production lines and automation systems.

Overall, the Doosan H2515 cobot is an excellent choice for businesses that require high-performance automation solutions with exceptional strength and flexibility. Its versatility, precision, and reliability make it a valuable asset in a variety of industries.