If you’re looking to automate your manufacturing line, 2D vision systems are a game-changer. These systems use cameras and smart software to capture images, check for defects, scan barcodes, and ensure everything runs smoothly. They’re reliable, fast, and perfect for tasks like quality control or assembly.

But with so many options out there, how do you choose the right one without overspending? This guide breaks it down for you. We’ll explain how 2D vision systems work, what features matter most, and how much you should expect to pay in 2025. Let’s help you make a smart, cost-effective choice for your operations.

Understanding 2D Vision Systems:

What are 2D Vision Systems?

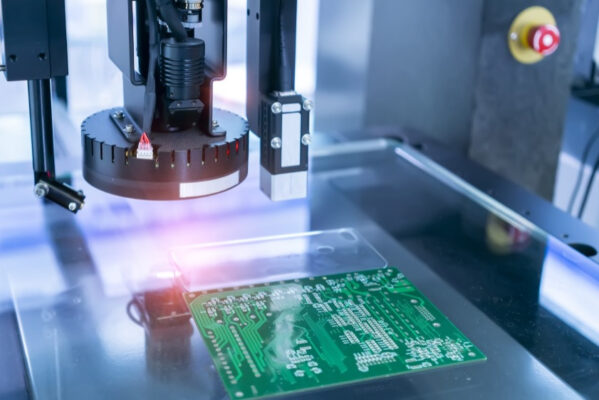

2D vision systems are a type of technology that use cameras to capture and analyze flat images for different uses. These systems are commonly used to detect patterns, scan barcodes, or check objects for quality. The main components of a 2D vision system include:

- Cameras: These capture the visual data.

- Optics: These help focus and improve the clarity of the images.

- Image Processing Software: This software analyzes the images to extract useful information.

These systems are particularly useful in environments like manufacturing lines for quality control, where they can quickly identify defects or ensure that products meet certain standards. They are also used in logistics for scanning labels and in retail for reading barcodes.

Key Differences Between 2D Vision Systems & 3D Vision Systems:

Dimensionality:

2D vision systems capture images in two dimensions, focusing only on length and width. They are ideal for simple tasks like barcode reading or basic inspections. 3D vision systems, however, also capture depth, making them useful for more complex applications that require understanding an object’s volume or exact shape, such as in detailed quality control or robotic guidance.

Cost & Complexity:

2D systems are simpler and cheaper, making them easy to set up and maintain. They’re fast and integrate easily into many operations. In contrast, 3D systems involve more advanced technology, which increases their complexity and cost. This makes them more suitable for specialized industrial tasks that require precise depth information.

Choosing the Right System:

The choice between 2D and 3D systems depends on your project’s specific needs. Use a 2D system for straightforward tasks that only need surface level details. For jobs requiring detailed 3D understanding, like adjusting to varying part sizes or complex assembly, opt for a 3D system. Each system has its strengths, so select based on the demands of your workflow.

This video explains how Cognex’s 2D machine vision systems optimize factory automation by improving inspection accuracy, efficiency, and product quality.

General Prices for 2D Vision Systems:

Price Range Overview:

The cost of 2D vision systems varies widely depending on their complexity, features, and the specific applications they are designed for. Generally, you can expect to find:

- Entry-Level Systems: These are typically priced between $1,000 to $3,000. They are suitable for basic tasks such as simple quality checks or barcode reading. These systems come with standard resolution and basic software capabilities.

- Mid-Range Systems: Prices for these systems range from $3,000 to $10,000. These systems offer better resolution, faster processing speeds, and more advanced features like better integration capabilities and enhanced image processing software. They are ideal for more demanding industrial applications that require higher precision.

- High-End Systems: These can cost anywhere from $10,000 to over $25,000. High-end 2D vision systems are equipped with state-of-the-art technology, including ultra-high-resolution cameras, robust software suites, and advanced analytics capabilities. They are typically used in applications where high precision and speed are critical, such as in high-speed automation lines or complex assembly checks.

Factors Affecting Prices of 2D Vision Systems:

Several factors can influence the cost of a 2D vision system:

Resolution & Image Quality:

Higher resolution cameras that provide clearer and more detailed images tend to increase the price.

Software Capabilities:

Systems with sophisticated software that can perform complex image analysis, integration with AI, and have adaptable learning capabilities usually come at a higher cost.

Durability & Specifications:

Systems designed to operate in harsh industrial environments with higher standards for dust, moisture resistance, and mechanical robustness are priced higher.

Brand & Support Services:

Established brands like Cognex and Keyence might offer systems at a premium, but this often includes better customer support, warranties, and reliable after-sales services.

5 Buying Tips for 2D Vision Systems:

Compatibility:

Ensure that the 2D vision system you choose is compatible with your existing equipment. This includes checking that the system can interface with your current hardware and software platforms. Compatibility reduces potential issues during integration and can lower overall costs by avoiding unnecessary replacements or upgrades.

Ease of Integration:

Look for systems that promise straightforward installation and configuration. Time saved on setting up and training staff on a new system translates directly into cost savings. Systems that come with pre-calibrated options or with intuitive user interfaces can significantly reduce integration efforts.

Feature Set vs. Needs:

Balance the features of a system against your actual needs. More features often mean higher costs, so prioritize systems that provide the functionalities essential for your operations. Consider factors like image resolution, processing speed, and the types of objects you need to inspect.

Support & Service:

After-sales support is crucial. Reliable customer service can greatly enhance the value of your purchase. Consider manufacturers who offer comprehensive support, including training, maintenance, and easy access to replacement parts.

Reviews & Recommendations:

Lastly, don’t overlook the importance of reviews and user feedback. Other users’ experiences can provide insights into the reliability and performance of the system in real-world conditions.

Conclusion:

When selecting a 2D vision system, prioritize a balance between cost, features, and how well it fits with your current equipment. Opting for the cheapest option might save money initially but could lead to higher costs later if it lacks necessary features or doesn’t integrate well with your setup. Choosing a system with good support and appropriate specs will improve efficiency and be more cost-effective in the long run. Consider your specific needs carefully to make a choice that will boost your operations.

Do You Want to Compare Different 2D Vision Systems?