Euclid Labs Moonflower Blue Alternatives & Competitors

Ranked Nr. 41 of 85 Robot Software

Top 10 Moonflower Blue Alternatives

- SOLOMON vision AccuPick 3D

- SOLOMON vision AccuPick – SmartPack

- Photoneo Bin Picking Studio

- Liebherr Group Robot vision technology packages - LHRobotics.Vision

SOLOMON vision AccuPick 3D

Bin pickingSOLOMON Vision AccuPick 3D utilizes AI-driven 3D machine vision to handle complex material handling tasks with high precision. It generates detailed point clouds to detect and manipulate random or unknown objects, regardless of their appearance, orientation, or spatial location. This technology is particularly effective in overcoming limitations associated with traditional vision systems, including issues with transparent, reflective, or irregularly shaped objects.

AccuPick 3D features advanced collision-free motion planning and a user-friendly graphic-based interface, which enhances its ability to execute complex pick-and-place tasks efficiently. Its compatibility with open platforms and auto-labeling capabilities streamline integration into various systems, eliminating the need for CAD files. This system is designed to handle soft, deformable, small, or overlapping objects with ease, making it suitable for diverse manufacturing and retail automation environments.

The system's key advantages include its ability to handle challenging conditions, such as transparent or reflective objects and complex backgrounds. By leveraging industry-leading AI and 3D vision technologies, AccuPick 3D provides a versatile and effective solution for automated bin picking and material handling.

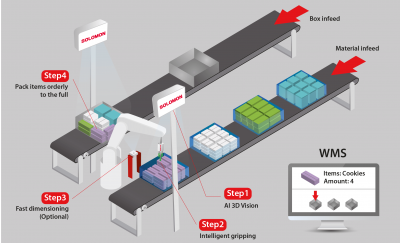

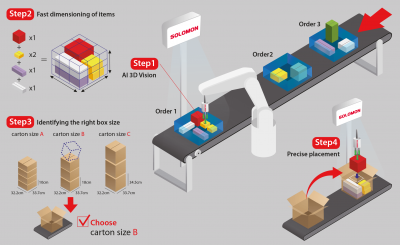

SOLOMON vision AccuPick – SmartPack

Bin pickingHuman-like vision to locate diverse objects

SmartPack relies on advanced neural networks and 3D vision to pick an unlimited amount of SKUs without being taught what they individually look like. This makes SmartPack uniquely suitable to handle a wide variety of items that are typically stored in fulfillment centers, logistics hubs, and corporate warehouses.

Vision controlled grippers to ensure the smooth handling of different objects

SmartPack may be used with a patented gripper that makes it possible to adjust its contact areas based on the size of the objects identified by the 3D vision system. This intelligent gripping system ensures that the small nearby items are not accidentally picked by large suction cups, while generating sufficient suction power to hold onto larger items when they are transported by the robot.

Fast dimensioning and precise placement of the objects in a box

Whether it’s identifying the right box size to fit a customer order, or filling a container methodically to minimize the slacked space, SmartPack can quickly scan the dimensions of the individual SKUs to be picked. This allows the system to instantly locate the optimal position in the box or bin in which the picked item should be placed.

Award-winning UI with seamless integration with all major robot brands

A winner of the 2020 Red Dot Best of Best award, AccuPick SmartPack comes with a simple user interface which can be used to build dierent packaging applications without any code writing. Furthermore SmartPack can be easily integrated with all major robot brands, PLCs, and WMS communications. Integrating multiple robots to increase throughput can also be easily set up through the UI.

AccuPick – SmartPack Smart Packaging Solution

Bin to Bin

Bin to Carton

Photoneo Bin Picking Studio

Bin picking

How does it work?

- Select the robot- For you and your projects, we have developed the largest database of robots. We are supporting great amount of robot models from various brands. And if you have a robot that is not in our list - get in touch and we will gladly provide assistance and integrate it into our Bin Picking Studio.

- Upload the gripper- Upload the CAD model of your gripping tool. The model of the gripper is used for tool point configuration in the virtual environment.

- Upload your object- All you need to start planning your bin-picking gripping points is a CAD model of the product you want to pick. Upload it into the Bin Picking Studio and immediately start working with it in a virtual environment.

- Set up gripping & tool points- The setup of bin picking begins with the selection of points where and how will the gripper grasp the object. Bin Picking Studio offers you full support also in this task. Thanks to the simple visual process you no heavy math involved.

- Load your environment- In this step, we will let the Bin Picking Studio know where will the picking take place. It is done again in the easiest fashion possible - by loading a CAD model of your picking cell. Immediately after the upload, the Studio offers you a 3D visualization available for work.

- Setup your part localization-Bin Picking Studio implements a built-in engine for setting up an object localization algorithm. The algorithm based on the CAD matching approach was developed by Photoneo to suits the use for bin-picking with a focus on speed and robustness.

- Robot to camera calibration- Robot calibration was never easier. With Photoneo’s Bin Picking Studio you no longer need expensive and specific objects or specially prepared calibration sheets. One round object in the shape of a sphere is enough. Calibrate and synchronize your scanner and robot via the intuitive guided program. You will immediately receive visual feedback that you are able to validate and evaluate throughout the entire calibration.

- Interactive debugging- And finally, it is time to pick. Utilize the ultimate advance debugging tools within the virtual environment. These will allow you to see how well was the solution prepared.

Liebherr Group Robot vision technology packages - LHRobotics.Vision

Bin picking | VisionLiebherr is making its expertise in the field of industrial robot vision applications available to a wide user group with the LHRobotics.Vision technology packages

The technology packages consist of a projector-based vision camera system for optical data collection and software for object identification and selection, collision-free withdrawal of parts, and robot path planning to the stacking point.

Software

Basic license:suitable for customers who only need to roughly set the gripped workpiece down. Path planning is not necessarily required for this. Due to the lack of robot model and obstacles, it is also suitable for customers who place less value on collision checking outside the bin, for example in cases where the gripper is never able to fully enter the bin.

Pro license:

The professional license offers unrestricted use of the LHRobotics.Vision software. This license is particularly suitable for customers who place value on full collision checking of the path from removal to possible stacking

Smart bin-picking software

Design a complex application without any programming knowledge at all. LHRobotics.Vision makes it possible. The intuitive graphical user interface enables quick entry of all necessary information using simple steps, starting with:

- Attaching workpieces

- Configuration of transport containers

- Models can be created directly in the software for simple geometry, or existing CAD data can be imported

Step by step to the right grip

In order to be able to realistically represent withdrawal of parts including all axis movements in the software, highly detailed grippers are created – even bendable grippers or a 7th or 8th axis can be represented. The interfering contour takes into account the current status of the gripper – open or closed. Again, existing CAD data can be accessed.

When the workpiece and gripper meet, the task is to define suitable picking positions. This can be done by visually positioning the gripper or by precisely defining the coordinates. Degrees of freedom can be tested, and even realistic removal cycles can be simulated with the LHRobotics.Vision Sim plugin. This enables the optimization of the gripper already within the software.

Integrated simulation possibilities with LHRobotics.Vision Sim

If changes are necessary, for example modified or completely new parts are to be gripped, you'll want to test in advance if it works. In our option package LHRobotics.Vision Sim, this possibility is included. As offline programming, i.e. without intervening in the running cell, the feasibility can be tested. The entire process can therefore be tested in the cell and put into operation in advance.

The environment in view

Once parts and grippers have been created, the periphery follows. The robot used is selected from the library to check the work area. Any obstacles can be taken into account:

- Input of obstacles present in the robot’s work area

- Hand-eye calibration of the system between sensor and robot

- Definition of framework conditions for collision-free withdrawal of parts

- Path planning