Assembly is where you put together various parts to create a final product. It’s crucial because if parts don’t fit or work together, your product can fail. Automation is changing assembly by making it faster and more accurate. Automated systems can handle repetitive tasks, reduce errors, and cut production costs. This boost in efficiency means you can focus on more complex manufacturing tasks. Embracing automation in your assembly process can greatly improve your production line’s efficiency and the quality of your products.

Understanding Assembly:

Definition of Assembly:

Assembly in manufacturing is the process of putting together individual parts to form a complete product. This step ensures that each component fits and works correctly within the final product.

Historical Context & Evolution:

Assembly has changed a lot over time. It started with all tasks being done by hand. During the Industrial Revolution, machines began to help workers. Now, you see automated and hybrid methods using advanced robotics and computers to improve production.

Key Components and Processes:

The assembly process involves several key components and steps:

- Parts and Components: These are the individual pieces that need to be assembled.

- Tools and Equipment: Items like screwdrivers, robotic arms, and conveyor belts used in the assembly.

- Assembly Line: The sequence of stations where parts are added or processes are performed.

- Quality Control: Ensuring each assembled product meets required standards.

Examples of Products:

Many products require assembly, such as:

- Automobiles: Cars are assembled from thousands of parts.

- Electronics: Smartphones, computers, and televisions are put together from various components.

- Furniture: Items like tables and chairs are assembled from individual pieces.

Types of Assembly Processes:

In manufacturing, there are two main types of assembly processes: manual and automated.

Manual Assembly:

Manual assembly involves workers using hand tools to put together parts. Examples include assembling furniture or small electronic devices.

Pros and Cons:

- Pros: Flexibility to handle complex and varied tasks. Easier to adapt to changes.

- Cons: Slower and prone to human error. Higher labor costs.

Automated Assembly:

Automated assembly uses machines and robots to perform repetitive tasks. Examples include car manufacturing and electronics production.

Pros and Cons:

- Pros: Faster production speeds, consistent quality, and lower long-term costs.

- Cons: High initial investment and need for specialized maintenance.

Choosing the right assembly process depends on your production needs, budget, and desired efficiency.

The Role of Automation in Assembly:

Automation in assembly means using machines and technology to perform tasks traditionally done by hand. It’s a game-changer for many manufacturers.

Benefits of Automation:

- Efficiency: Automated systems work faster than humans, speeding up production.

- Consistency: Machines produce the same results every time, reducing errors.

- Cost Savings: While the initial investment is high, automation lowers labor costs and minimizes waste over time.

Examples of Automated Assembly Systems:

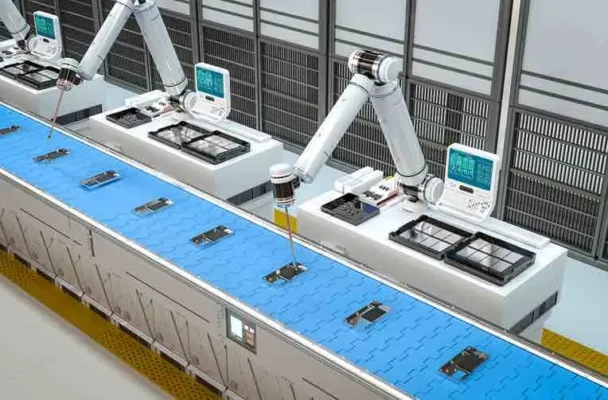

- Robotic Arms: These are used for tasks like welding, painting, and assembling parts.

- Conveyor Systems: These move parts from one assembly station to another, streamlining the process.

- Vision Systems: These systems inspect parts for quality, ensuring that only the best products move forward.

Key Technologies in Automated Assembly:

Robotics:

Robots are essential in automated assembly. You can use different types, like industrial articulated robots, cobots, SCARA, and delta robots. Articulated robots are versatile and perfect for tasks like welding and assembly. SCARA robots are best for pick-and-place tasks. Delta robots are great for high-speed sorting and packaging.

Vision Systems:

Vision systems are crucial for accuracy and quality. You can use 2D vision systems for tasks like barcode reading. 3D vision systems create depth maps, helping robots handle complex shapes. These systems reduce errors and improve precision, ensuring your products meet high standards.

Grippers & End Effectors:

Grippers and end effectors are like the hands of your robotic system. You can choose from vacuum, pneumatic, and electric grippers. Vacuum grippers work well on flat, smooth surfaces. Pneumatic grippers handle various shapes and sizes. Electric grippers offer precise control. Select the right gripper based on your specific needs for efficient and effective assembly.

Applications of Automated Assembly:

Automotive Industry:

In the automotive industry, automated assembly is key. You can use it for welding car frames, installing engines, and assembling interiors. Robots ensure each task is done quickly and precisely, improving the quality and speed of your production.

Electronics Manufacturing:

For electronics, automated assembly is essential. It helps you assemble circuit boards, smartphones, and other devices. Robots place tiny parts accurately, reducing errors and boosting efficiency.

Consumer Goods:

In consumer goods, automated assembly helps put together household products and manage packaging. You can use it for assembling appliances, toys, and packaging items for shipping. Automation makes production faster and maintains consistent quality.

Medical Devices:

Precision is critical for medical devices. Automated assembly helps you make surgical tools and diagnostic equipment with high accuracy

4 Steps to Implement Automated Assembly:

1. Assessing Your Needs:

Start by identifying the processes you can automate. Look at tasks that are repetitive, time-consuming, or prone to errors. Determine where automation will have the most impact on your production efficiency.

2. Selecting the Right Equipment:

Choose the equipment that fits your needs. Consider factors like compatibility with your current systems, scalability for future growth, and cost. Ensure the equipment can handle your specific tasks and production volume.

3. Integration & Setup:

Proper setup and calibration are crucial. Integrate the new equipment into your existing production line smoothly. Make sure everything is calibrated correctly to avoid issues and ensure optimal performance.

4. Training & Maintenance:

Train your staff to operate and maintain the automated systems. Proper training ensures that your team can handle the equipment effectively and address any issues that arise. Regular maintenance is key to keeping your systems running smoothly and efficiently.

3 Challenges in Automated Assembly:

1. Initial Costs:

The high upfront cost is a major challenge. Buying automated equipment is expensive. You need to budget for machines, software, and installation. This can be tough, especially if you run a small operation.

2. Technical Complexity:

Automated systems need skilled workers. You will need experts to manage, program, and maintain the equipment. Finding and training these experts can be hard and costly. Without them, your automated systems might not run smoothly.

3. Adaptability:

Flexibility is another hurdle. Your automated systems must handle different products and adapt to production changes. This requires careful planning and investment in versatile equipment. If your production needs change, you might need to reconfigure or upgrade your systems, adding to the complexity and cost.

Conclusion:

Automated assembly can greatly improve your manufacturing process. It makes production faster, improves quality, and reduces long-term costs. However, you need to manage high initial costs, find skilled workers, and ensure your systems are flexible. With careful planning and the right technology, you can overcome these challenges. By automating your assembly line, you will boost efficiency and product quality, helping you stay competitive. Start exploring automation today and see the positive impact on your production.