Thinking about boosting your production line? Industrial robots are key. These machines are more than tools; they’re game-changers in making work faster, better, and safer. Forget the old days of all manual work. Today, robots add a new level of smarts and power to manufacturing, from autos to snacks. If staying ahead matters to you, knowing what an industrial robot offers is crucial.

Let’s unpack how these tech wonders can transform your factory floor.

What is an Industrial Robot?

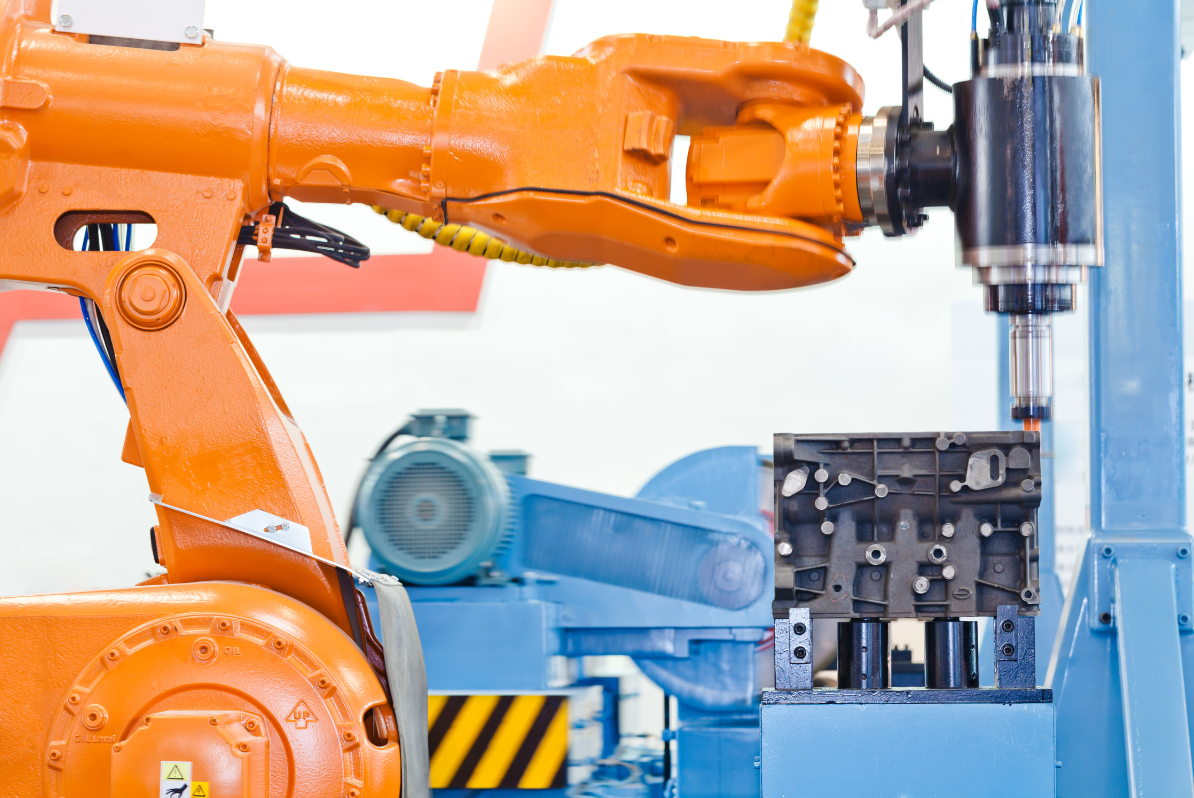

Industrial robots are the powerhouse allies in your manufacturing arsenal. Imagine a robotic arm that can weld, assemble, or paint with precision 24/7. That’s an industrial robot for you. These aren’t one-trick ponies. They can be reprogrammed and adapted to tackle various tasks, making them versatile players on your production line.

What sets these robots apart? Three things: flexibility, intelligence, and autonomy. Flexibility means they can switch from one job to another with minimal fuss. Intelligence is their ability to make decisions based on the data they receive. Autonomy allows them to operate independently, without needing constant human guidance.

You might wonder, “Isn’t that just like any machine?” Here’s the difference: while traditional machines do one task repeatedly without change, industrial robots can learn and adjust. They’re designed to interact with their environment in more complex ways, thanks to sensors and smart programming.

This adaptability makes them ideal for a range of applications, from handling delicate electronics to lifting heavy metal parts. They fit right into your existing setup, working alongside your team or taking on the heavy lifting solo.

By integrating industrial robots, you’re not just upgrading your machinery; you’re opening the door to a new era of efficiency and innovation. These robots are transforming industries, making it possible to produce more, with higher quality and lower costs. As you consider bringing robots into your space, think of them as multifunctional tools ready to take on the challenges of modern manufacturing.

Types of Industrial Robots:

Let’s dive into the types of industrial robots you can choose from, each suited for specific tasks on your production floor.

1. Articulated Robots:

Articulated robots are like flexible arms with joints. They’re perfect for jobs that need a human touch, such as assembling parts or precise welding. Think of them as your go-to for complex tasks.

2. SCARA Robots:

SCARA robots specialize in swift, precise movements in a limited space. Ideal for speedy assembly or moving items quickly, they’re your pick for high-speed, accurate tasks.

3. Cartesian Robots:

Cartesian robots move straight up, down, left, and right. If you need straightforward, precise tasks like placing objects or 3D printing, they’re your best bet.

4. Delta Robots:

Delta robots are the speed kings, moving items super fast. Set them up for packaging or sorting jobs where speed is crucial. They work like a charm on fast-moving production lines.

5. Cobots:

Cobots are your friendly sidekicks, designed to work safely alongside humans. They’re versatile, easy to use, and great for tasks like checking product quality or helping with light assembly.

Each robot type brings something special to the table. By understanding what each does best, you can choose the right robot for your needs, making your production line more efficient and innovative.

To determine which option is best for your automation needs, check out this article:

What Are Industrial Robots Used For?

Industrial robots are not just machines; they’re your powerhouse partners ready to take on a variety of tasks. Here’s how they can make a big difference in your operations:

1. Loading & Unloading:

For machine tending, robots are a game changer. They load and unload machines tirelessly, keeping your production moving smoothly without breaks or mistakes.

2. Welding:

In welding, precision and consistency are key. Robots deliver on both, executing perfect welds every time. They work fast and flawlessly, making your welding process faster and reducing waste.

3. Assembly:

Assembly lines benefit hugely from robots. They put together parts quickly and accurately, increasing your output and ensuring each product meets your high standards.

4. Painting & Coating:

Painting and coating? Robots have it covered. They apply materials evenly, in exactly the right amounts, every single time. This not only saves materials but also keeps your workers safe from harmful fumes.

5. Picking, Packing & Palletizing:

And let’s not forget picking, packing, and palletizing. Robots sort, pack, and stack with incredible speed and accuracy, optimizing your warehouse operations and getting products out the door faster.

By bringing industrial robots into these areas of your manufacturing process, you’re not just improving efficiency; you’re setting a new standard for quality, safety, and productivity. They’re the reliable, tireless workers that keep your operation running at its best, day in and day out.

Need Free Advice For Your Robot Project?

5 Benefits of Using Industrial Robots:

Adding industrial robots to your line boosts your work in big ways. Here’s how:

1. Boost Productivity:

Productivity jumps because robots don’t stop. They work all day, every day, so you make more, faster.

2. Ensure Quality:

Your products get better. Robots are precise, so everything they make is spot-on. This cuts down on waste and makes sure your customers get the best. Robots make your workplace safer. They do the risky jobs, cutting down on accidents and keeping your team safe.

3. Increase Flexibility:

They’re also super flexible. Need to change a task? Reprogram your robot and it’s on it. This lets you keep up with new trends and demands easily.

4. Save Costs:

Cost-wise, robots are a smart investment. They might seem pricey at first, but they save you money on labor and mistakes in the long run.

5. Protecting the Environment:

They’re even good for the planet. Robots use materials and energy efficiently, reducing waste. And they can work in harsh conditions without harm.

In short, robots make your production line faster, safer, and more efficient. They save you money and help the environment. It’s a smart step for any business looking to improve.

To learn more about the benefits of an Industrial Robot, check out this article:

5 Tips for Smart Planning for Robot Integration:

Before you dive into robots, here’s what you need to think about:

Check Your Wallet:

Robots cost a lot at first. But, they work non-stop and cut down mistakes, saving you money later. Make sure they’ll pay off for you in the long run.

Fit With Your Stuff:

Make sure the robot you pick works well with your current setup. You want to boost your efficiency, not start from scratch.

Train Your Team:

Your crew needs to know how to use these robots. Investing in their training is key. It’s good for them and great for your business.

Upkeep is Key:

Robots need care to keep running well. Plan for regular maintenance to avoid unexpected downtime.

Safety Comes First:

Pick robots that are safe and fit into your safety plans. The aim is to make your workplace safer for everyone.

Getting robots is exciting and can really change how you work. With some smart planning, you can make sure it’s a change for the better.

The Future of Industrial Robots:

Robots are getting smarter thanks to AI. Soon, they’ll learn as they work, getting better every day. And cobots? They’re the future. These robots work right next to you, making jobs safer and teams more productive. They’re here to help, not take over.

Green tech is big, too. Tomorrow’s robots will be energy-savers and waste-cutters, making your factory cleaner and greener. Good for the earth, great for your bottom line.

Conclusion:

Thinking about improving your production line? Industrial robots can make a big difference. They work faster, more accurately, and safely compared to manual labor. These robots can handle tasks like welding, assembly, and packaging, adapting easily to various jobs. By using them, you boost your efficiency and quality. These robots learn and adjust to perform complex tasks with minimal downtime.

Do you want to compare different Industrial Robots?