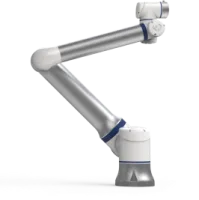

YASKAWA HC10DTP Specifications

Ranked Nr. 22 of 207 Cobots

The YASKAWA HC10DTP is a human-collaborative robot designed for versatile applications in harsh industrial environments. It boasts a robust build with a high IP67 protection rating, ensuring resistance against dust and liquids, which is crucial for deployment in demanding conditions. The cobot also features food-grade grease lubrication in all its joints and a special drip-proof coating, making it suitable for sensitive and hygienic environments such as food processing.

The HC10DTP offers a 10 kg payload and an extended reach of 1,379 mm, paired with a repeatability of ±0.05 mm. These specifications allow it to perform with high precision in various tasks, ranging from simple handling and assembly to more complex functions like machine tool loading and quality inspection. Its design facilitates easy integration into existing production lines without the need for extensive modifications, enhancing its utility as a flexible automation solution.

Operational ease is a key attribute of the HC10DTP, featuring hand guiding and Direct Teach buttons for intuitive programming and quick task setup, making it accessible for both experienced operators and newcomers. The cobot can switch between safely monitored slow operations and full-speed tasks, optimizing cycle times and productivity. Pre-routed media cables within the arm minimize external cable clutter, further enhancing its operational efficiency and safety in collaborative workspaces.

| Linear speed | 2000 mm/s |

| Industry |

|

| IP classification | IP67 |

| Payload | 10 kg |

| Reach | 1379 mm |

| Repeatability | 0.1 mm |

| Number of Axes | 6 |

| Footprint | 255 mm |

| Robot mass | 58 kg |

| Extra info | Food grade grease: Cobot can be used in the food industry |