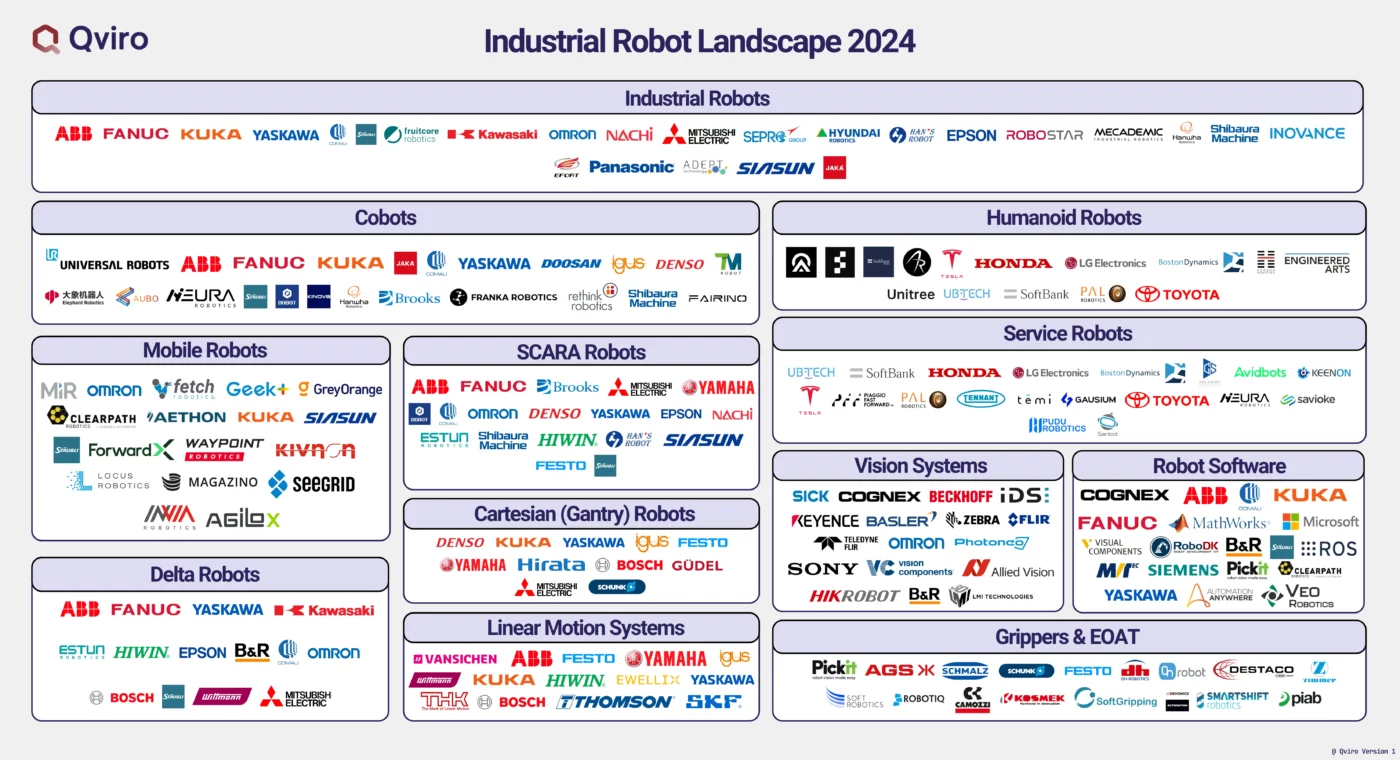

In 2024, the industrial robotics field is packed with choices. If you’re looking to improve your manufacturing line or invest in automation, it’s important to know the current landscape. This article will help you understand the key players and the latest technologies. We’ll walk you through everything from traditional industrial robots to the newest collaborative and humanoid robots. By the end, you’ll know exactly where the industry stands and how to choose the right solutions for your needs

What is an Industrial Landscape?

The industrial landscape is the overall environment and market conditions within a specific industry. In robotics and industrial automation, it includes the key players, technologies, trends, and challenges that influence how automation solutions are developed and used.

Why is it Important?

Understanding the industrial landscape is essential when you’re considering robotics or automation for your operations. It helps you identify the most reliable products and the companies leading in innovation. By knowing the landscape, you can make better decisions about which solutions to invest in, ensuring that your automation aligns with current trends and future advancements.

If you’re interested, you can download a high-resolution image of the industrial landscape.

Click here to download the image.

Key Players in Industrial Robotics:

Major Industrial Robot Manufacturers:

If you’re considering industrial robots, you’ll likely come across names like ABB, FANUC, KUKA, and Yaskawa. These companies are leaders in the industry for a reason. They consistently deliver reliable, innovative robots that can handle a variety of tasks in manufacturing. Whether you need a robot for precision work, high-speed tasks, or heavy lifting, these brands have options that can meet your specific needs. Their strong market position comes from their ability to adapt to changing demands and deliver high-quality products.

Cobot (Collaborative Robots) Innovators:

Collaborative robots, or cobots, are gaining popularity fast. Companies like Universal Robots, ABB, FANUC, KUKA, and DOOSAN are leading the way in this space. Cobots are designed to work alongside humans, making them perfect for tasks that require flexibility. These companies are constantly improving cobot technology to make them easier to use and more productive. If you’re looking to increase efficiency while keeping safety a priority, cobots from these brands are worth considering.

Humanoid Robots:

Humanoid robots are also making strides in the industry. Brands like Tesla, Honda, LG Electronics, and Boston Dynamics are developing robots that can mimic human actions. These robots are finding their place in industries like healthcare, customer service, and entertainment. If your operations could benefit from robots that interact with people and perform complex tasks, these companies offer some of the most advanced options available.

Looking to compare industrial robots and find the right solution for your needs? Use Alina, your AI Automation Consultant from Qviro, to explore specs and make informed decisions. Get started with Alina now!

GET STARTED WITH ALINA NOW!

Emerging Technologies & New Entrants:

Mobile Robots:

Mobile robots are making a big impact across various industries. Companies like MiR, OMRON, Geek+, and Clearpath are at the forefront. These robots can move on their own, thanks to advanced navigation and AI. They can avoid obstacles, plan routes, and adapt to changing environments. If you need robots to transport goods, manage inventory, or assist with logistics, these options offer flexible solutions tailored to your needs.

Delta & SCARA Robots:

Delta and SCARA robots are your go-to for tasks that demand precision and speed. ABB, FANUC, Yaskawa, and Yamaha are top names in this area. Delta robots are great for fast pick-and-place tasks, often used in packaging and assembly. SCARA robots are perfect for horizontal movements, ideal for assembly, palletizing, and inspection tasks. These robots are designed to perform repetitive tasks with high accuracy, helping you improve efficiency in your operations. If you need precision and speed, consider adding Delta and SCARA robots from these brands to your setup.

Supporting Technologies: Vision Systems & Grippers:

Vision Systems:

Vision systems are essential in making your automation more accurate and efficient. They enable your robots to see and interpret their surroundings. SICK, COGNEX, and KEYENCE are key players in this space. Their systems are used for tasks like inspection, sorting, and quality control. If you’re looking to improve precision in your processes, adding a vision system from one of these companies can make a significant difference.

Grippers & End-of-Arm Tooling (EOAT):

Grippers are what allow your robots to handle objects. Brands like Schunk, OnRobot, Destaco, and Festo provide a variety of grippers for different tasks. Whether you need to pick up fragile items or handle heavier parts, there’s a gripper that fits your needs. The right gripper increases your robot’s flexibility and ability to perform various tasks with precision. By choosing the correct gripper, you can enhance your automation setup and ensure your robots can adapt to different applications effectively.

Software & Integration Solutions:

Robot Software:

The software is key to how well your robot performs. Providers like Cognex, ABB, KUKA, FANUC, and Siemens offer software that handles programming, simulation, and integration. This software lets you control and optimize your robot’s tasks, making sure everything runs smoothly and efficiently. Whether you’re setting up a new task or simulating a full production line, using the right software will make your work easier and more reliable.

Linear Motion Systems:

Linear motion systems are essential for precise movement in your automation setup. Brands like Bosch, Thomson, Vansichen and SKF provide systems that work seamlessly with your robots, allowing them to move in a straight, controlled path. These systems are especially useful in tasks like assembly or material handling, where smooth and accurate motion is critical. By adding dependable linear motion systems, you can improve the efficiency and accuracy of your operations, helping you get better results from your automation.

Market Trends & Future Outlook:

Market Growth & Investment:

In 2024, the industrial robot market is growing rapidly. The global market is on track to reach $43.8 billion by the end of the year. This growth is fueled by rising demand in manufacturing, logistics, and healthcare. Investments in robotics are also up, with a 15% increase in funding compared to last year. Emerging markets, especially in Asia, are adopting robots at a fast pace, driving this expansion.

Future Technologies:

The future of robotics looks promising. AI is becoming more important, making robots smarter and more adaptable to your needs. Collaborative robots (cobots) are also expected to grow, with the market likely to expand by 20% annually in the coming years. Humanoid robots are advancing too, with new applications in complex environments. These trends mean that robots will play an even bigger role in your operations, helping you boost efficiency and productivity in new ways.

Conclusion:

In 2024, the industrial robotics field is more active than ever. To make the best decisions for your operations, it’s important to understand the key players, new technologies, and current trends. By staying informed, you can choose solutions that fit your needs and keep you competitive. Whether you’re investing in new robots or upgrading your systems, knowing the landscape will help you get the most out of your automation. The choices you make now will play a big role in your future success in industrial automation.