BOOST YOUR MANUFACTURING WITH MACHINE TENDING

Elevate your production line with machine tending robots: Get faster, more precise work done without the sweat.

1. What is Machine Tending?

Machine tending is the process where you use robots or automated systems to load raw materials into a machine and then unload the finished products. Think of it as having a robotic helper in a manufacturing setup that handles the repetitive task of feeding machines with what they need to start the production process and then taking out the finished goods once they're done.

This automation step is crucial because it boosts your production line's efficiency. By employing robots for these tasks, you're making it safer and more precise. Robots don't tire, which means they can work all day without breaks, ensuring a consistent output rate. Plus, they're accurate, reducing the chances of errors that can happen when humans do these repetitive tasks.

By integrating machine tending robots into your manufacturing process, you're essentially freeing up your employees to focus on more complex and less monotonous tasks. This not only optimizes your production efficiency but also improves workplace safety by minimizing human involvement in potentially hazardous operations.

2. Which Industries Benefit From Machine Tending?

Automotive & Aerospace: Precision Non-Stop

If you're in the business of making cars or planes, every tiny detail counts. Machine tending robots are your go-to for making sure every part is perfect. They work non-stop, keeping your production lines moving smoothly and ensuring everything from engines to wings meets the highest safety and precision standards.

Electronics: Gentle Touch for Tiny Parts

In electronics, where every component is crucial and often fragile, robots are a game changer. They handle small, delicate parts with care, putting together your gadgets efficiently and without errors. This means you can speed up production without worrying about mistakes or damage, staying ahead in the fast-paced tech world.

Metal Fabrication & Plastics: Strong and Precise

Working with heavy metals or plastics? Robots can take the weight off your shoulders, literally. They're built for tough tasks, like lifting heavy loads or precisely molding materials, making your job safer and your products more consistent. This is essential in environments where precision and safety are key.

Customized Solutions for Every Industry

No matter what you make—vehicles, electronics, or materials—machine tending robots can be customized to fit your unique manufacturing needs. They not only boost your efficiency and product quality but also pave the way for innovation, helping you explore new possibilities in your industry.

Featured Machine Tending Cobots:

3. What Types of Machines Can Be Tended by Robots?

Cobots: The Collaborative Edge

Cobots are a special kind of robot designed to work alongside humans. Unlike traditional industrial robots that often work behind safety barriers, cobots can safely interact with your workforce. They're perfect for tasks that require a human touch combined with robotic precision and endurance, bridging the gap between fully automated and manual operations.

Industrial Robots: The Heavy Lifters

Industrial robots are your go-to for heavy-duty tasks. They operate with speed and precision on a larger scale, ideal for environments where high volume and efficiency are key. These robots take on the most challenging tasks, working tirelessly to keep your production lines moving.

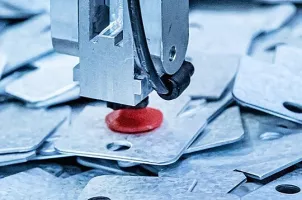

CNC Machines: Unmatched Precision

When it comes to CNC machines, both industrial robots and cobots shine. They can precisely load and unload parts, ensuring operations like milling, drilling, or cutting are done with exceptional accuracy. This precision is crucial for high-quality production.

Injection Molding Machines: Elevating Consistency

In the plastics industry, the repetitive task of loading and unloading injection molding machines is where robots excel. They guarantee consistent quality and quicker production cycles, making your plastic products better and faster to produce.

Presses and Stamping Machines: Strength Meets Finesse

For those using presses or stamping machines, robots are indispensable. They're designed to manage the demanding work of moving heavy materials and accurately placing them, boosting both safety and productivity in metalworking tasks.

4. How Does Machine Tending Improve Manufacturing Efficiency?

Work Around the Clock:

Imagine your machines running non-stop, day and night. That's what robots offer. They don't need breaks, meaning your production never pauses, and you get more done.

Faster, Error-Free Work:

Robots work quickly and don't make mistakes. They keep your production speedy and flawless, ensuring every product meets your high standards.

Let Your Team Shine:

While robots handle the repetitive stuff, your employees can focus on tasks that need human intelligence and creativity. This not only boosts your output but also keeps your team happy and engaged.

Say Goodbye to Downtime:

Mistakes can slow you down. Robots help avoid these, keeping your machines humming smoothly. Less downtime means more production and savings.

Your Takeaway

By adding machine tending robots to your workflow, you're setting up for non-stop production, impeccable quality, and happier employees. It's an all-around boost for your business.

5. Can Machine Tending Robots be Integrated into Existing Production Lines?

Wondering if you can fit robots into your current setup? Absolutely. Here's how.

Perfect Fit for Your Line:

Robots are designed to blend into your existing production lines smoothly. They're adaptable, meaning they can work with the machines you already have, doing tasks like loading materials or assembling parts.

Customization is Key:

You can tailor these robots to meet your specific needs. Whether your line is big or small, there's a robot that can match your space and task requirements. They come with various tools and can be programmed to perform exactly how you need them to.

Tech Support on Your Side:

Integrating robots might sound complex, but you're not alone. Experts can help set them up and ensure they're working well with your current systems, making the transition smooth and stress-free.

6. How Do You Choose the Right Robot for Machine Tending?

Choosing the right robot for machine tending is crucial. Here’s how you can make the best choice.

Understand Your Needs:

First, look at what you need. Think about the size and weight of the items you’re working with and the type of tasks you need the robot to perform. This will help you narrow down your options.

Space Matters:

Consider how much space you have. Some robots need more room to operate than others. Make sure you choose one that fits comfortably in your workspace without disrupting your existing setup.

Precision and Speed:

Decide how fast and precise the robot needs to be. If you’re working with delicate parts or need things done quickly, you’ll need a robot that can keep up with your demands.

Future-Proofing:

Think about the future. Choose a robot that can adapt as your business grows and changes. This means looking for robots that are easy to reprogram or upgrade.

Your Guide to the Right Choice:

By understanding your needs, considering your space, and thinking about the future, you can select the right robot for your machine tending tasks. It’s about finding the balance between what you need now and what you might need later.

7. Why is Vision Systems Important in Machine Tending?

Vision systems give your robots the ability to "see." Here's how they change the game in machine tending.

Guiding Your Robots:

Think of vision systems as the eyes for your machine tending robots. They help robots identify where parts are, how they're oriented, and even if they're the right quality. This means your robots can work smarter and make decisions on the go.

2D vs. 3D: Picking the Right View:

2D Vision Systems: Great for tasks where parts are on a single level and the complexity is low. They're like taking a photo; they see the length and width but not depth.

3D Vision Systems: These are for when you need to understand the depth, like how tall something is or how it's positioned in space. Perfect for more complex tasks.

Why Vision Systems Matter to You:

With the right vision system, your robots can do their jobs more effectively, making your production line more efficient. Whether you're dealing with simple or complex parts, choosing the right 2D or 3D system ensures your robots have the vision they need to succeed.

Featured Machine Tending 2D Vision Systems:

Featured Machine Tending 3D Vision Systems:

8. Can Machine Tending Robots Adapt to Different Tasks?

Machine tending robots are more than just one-task wonders. They're built to adapt to a variety of tasks. Here's how they can fit into multiple roles in your production line.

Quick Learners:

These robots are quick learners. With the right programming, they can switch from one task to another, like moving from loading raw materials to assembling parts. This means you can use them for different stages of your manufacturing process, making your workflow more flexible.

Tool Changers:

Robots can also switch tools. Imagine a robot that can change its grip based on the task—from holding a metal sheet to picking up a delicate component. This ability allows them to handle a wide range of materials and tasks efficiently.

Your Production, Supercharged:

By integrating adaptable machine tending robots, you're not just investing in a single function. You're getting a versatile team member that can grow with your production needs, ready to take on new tasks as your business evolves. It's like having a workforce that never stops learning and improving.

9. What Maintenance Do Machine Tending Robots Require?

Regular Check-Ups:

Just like any machine, your machine tending robots need regular maintenance. This means checking them over for any wear and tear, making sure all their parts are in good shape, and keeping them clean. A well-maintained robot is a reliable one.

Software Updates:

Don’t forget about the brain of your robot—the software. Keeping the software up to date is crucial. Updates can improve performance, add new features, and fix any bugs. It's like updating your phone; it keeps things running smoothly.

Part Replacements:

Sometimes, parts wear out and need replacing. Staying on top of this keeps your robots working efficiently and prevents bigger problems down the line. Think of it as changing the oil in your car; it’s a small task that has a big impact on performance.

Your Role:

By taking care of these maintenance tasks, you ensure your robots continue to work hard for you, making your production line more efficient and reliable. It's about giving a little to get a lot in return.

10. Can Machine Tending Robots Work with Different Material Types?

Machine tending robots are not limited by material types. They're equipped to handle:

Metals: Including steel, aluminum, and brass, perfect for automotive or aerospace parts.

Plastics: From rigid materials like polycarbonate to flexible ones like silicone, suitable for consumer goods and packaging.

Composites: Such as carbon fiber or fiberglass, used in high-strength applications like sporting goods or automotive components.

Ceramics and Glass: For precision handling in electronics or home goods manufacturing.

Swap Tools, Not Robots:

The key to their adaptability is interchangeable tools. Depending on what you're working with, you can switch out the robot's end-of-arm tooling to grip, lift, and manipulate materials safely and efficiently.

Featured Machine Tending Grippers:

Need help or have questions? Contact us or book a meeting with Sven, our expert, for personalized support.