QUALITY INSPECTION GUIDE: EXCELLENCE IN AUTOMATION

Ensuring Product Perfection Every Step of the Way

1. What is Quality Inspection?

Quality inspection is a crucial process you'll encounter in manufacturing and production. It's where experts examine your products to ensure they meet specific standards of quality, safety, and efficiency before they reach the market.

Imagine buying a toy, a smartphone, or even food; you expect these items to work perfectly, be safe, and look good. That's where quality inspection comes in. Inspectors use a variety of tools and techniques to check every little detail, from the materials used to the final product's functionality.

This process helps prevent defective items from being sold, ensuring you get the best possible products. It's not just about catching mistakes; it's also about continuously improving the manufacturing process to make sure future products are even better.

Quality inspection is your assurance that what you buy has passed a strict check-up for excellence.

2. Why is Quality Inspection Important?

Quality inspection is vital because it directly impacts your satisfaction and safety. Think about it: when you purchase a product, you expect it to work as advertised, last a reasonable amount of time, and, most importantly, be safe to use. Quality inspection makes sure of that. It identifies any defects or issues before the products reach you, reducing the risk of accidents or malfunctions.

Moreover, it helps maintain a brand's reputation. A single faulty product can lead to unhappy customers and negative reviews, affecting a company's success. By ensuring everything meets high standards, quality inspection keeps you happy and loyal to the brands you trust.

It's not just about catching errors; it's about delivering excellence and safety to your doorstep. Quality inspection safeguards your investments, ensuring you get value for your money and trust in the products you use daily.

Featured Quality Inspection Cobots:

3. What are the Types of Quality Inspections?

Quality inspections can be grouped into three main types, ensuring your products meet all necessary standards from start to finish.

Pre-Production Inspection (PPI):

Before mass production kicks off, materials and components are checked. This ensures everything is up to par, preventing any issues right from the start.

During Production Inspection (DUPRO):

This happens once some of your product has been made. It's a way to catch and fix problems early in the manufacturing process, ensuring the rest of production runs smoothly.

Pre-Shipment Inspection (PSI):

This is the final check before products are sent your way. It verifies the quantity, quality, and packaging meet your expectations and standards.

These types cover the entire production cycle, from before manufacturing begins to the final steps before shipping, ensuring you receive only the best quality products.

4. When Should Quality Inspection Be Performed?

Quality inspection should be performed at key stages during the production process to ensure you receive products of the highest standard.

Before Production Starts (Pre-Production Inspection):

This step ensures all materials and components meet your requirements before manufacturing begins, saving you from potential issues down the line.

During the Manufacturing Process (During Production Inspection):

This inspection is crucial once 10-15% of the production is complete. It allows for early detection of defects or problems, giving you time to correct them without significant delays or costs.

Before Shipping (Pre-Shipment Inspection):

When 80-100% of the goods are ready and packaged, a final inspection is conducted. This ensures that the finished products meet your quality standards and specifications before they are shipped to you.

Performing inspections at these stages helps maintain quality throughout the production process, ensuring you get exactly what you ordered, without any unpleasant surprises.

5. What Tools and Equipment are Used in Quality Inspection?

In quality inspection, using cobots, short for collaborative robots, along with a few key tools, makes checking the quality of products easier and safer. Let's simplify how these tools work together:

Cobots:

These friendly robots work safely next to people. They can help with inspecting products by holding them up for inspection or moving them to the right spot without needing a lot of space or special safety equipment.

2D and 3D Vision Systems:

These cameras take pictures or 3D scans of the products to find any defects. When used with cobots, they can look at products from different angles to make sure nothing is missed.

Grippers:

These are like robot hands that can hold onto products. They help the cobot move items under the vision systems for a thorough check.

Think of cobots as helpful assistants that make quality inspection faster, safer, and more accurate. They work alongside humans and use cameras and grippers to ensure every product meets high-quality standards before it reaches you.

6. How is Quality Inspection Data Collected and Used?

Quality inspection data is collected and used in a straightforward way to ensure you get the best products. Here's how it works, focusing on key tools:

Using Tools Like Cameras and Sensors:

Cameras (part of 2D and 3D Vision Systems) take pictures of the products. Sensors check things like temperature or pressure. These tools help spot any problems with the products, like defects or parts not put together correctly.

Robots and Cobots:

Robots, including cobots (collaborative robots), can be fitted with cameras and sensors. They handle products, move them around, and use their tools to check quality. Cobots are special because they're designed to work safely with people, making them perfect for tasks needing a human touch.

Gathering Data:

All the information from cameras, sensors, and robots is collected into a computer system. This data shows if the products meet the quality standards.

Making Improvements:

By looking at the collected data, companies can find out where the manufacturing process can be improved. This means they can fix any issues to make sure future products are even better.

This process helps ensure that the products you use are safe, reliable, and of high quality.

Featured Quality Inspection 2D Vision Systems:

7. What Standards Guide Quality Inspection?

Quality inspection is guided by specific standards to ensure products are safe, efficient, and reliable. These standards help companies know exactly what to aim for when checking their products. Here are some key ones:

ISO 9001:

This is a global standard for quality management systems. It helps companies consistently meet customer and regulatory requirements. If you're buying products from a company with ISO 9001 certification, you can be more confident in their quality.

ANSI/ASQC Z1.4 & ISO 2859:

These standards specify how to do sampling inspections. They tell companies how many products to check out of a batch to decide if the whole batch is good. This helps ensure that only high-quality products reach you.

ISO/TS 16949:

Specific to the automotive industry, this standard focuses on continuous improvement, emphasizing defect prevention and reducing variation and waste in the supply chain.

These standards are like rulebooks for quality inspection in industrial automation, making sure that the products you use meet high quality and safety criteria.

8. What is the Difference Between Quality Inspection and Quality Control?

Quality inspection and quality control are two crucial steps in making sure you get great products, but they focus on different parts of the process.

Quality Inspection:

This is about checking the products themselves. It happens at specific points, like before, during, or after production. The main goal is to look at each item or a sample from a batch to see if there are any defects. Think of it as a "snapshot" check to make sure the products meet the set standards at that moment.

Quality Control:

This is the bigger picture. It includes quality inspection, but it's also about managing the whole process to make everything better over time. Quality control involves setting the standards, deciding how tests are done, and figuring out ways to prevent mistakes in the first place. It's an ongoing effort to improve how products are made, ensuring consistent quality.

So, while quality inspection is about checking products, quality control is about managing the entire process to keep making those products better.

Featured Quality Inspection 3D Vision Systems:

9. What Challenges are Associated With Quality Inspection?

Quality inspection faces several challenges that can affect the quality of the products you receive.

Detecting Complex Defects:

Some defects are hard to spot, especially in products with complex designs or materials. This can make it tough to catch every issue, risking faulty products getting through.

Keeping Up with High Speeds:

In fast-paced production lines, inspectors and machines must work quickly without missing defects. Balancing speed and accuracy is challenging but crucial to meet demand without compromising quality.

Adapting to New Technologies:

As products evolve, inspection processes must too. Keeping up with new manufacturing technologies and materials requires constant updates to inspection methods and training for inspectors.

Cost:

High-quality inspection tools and training inspectors are expensive. Finding ways to maintain high standards while controlling costs is a continuous challenge.

These challenges make quality inspection a demanding but vital part of producing reliable, safe products. Overcoming them ensures you get the best quality items every time.

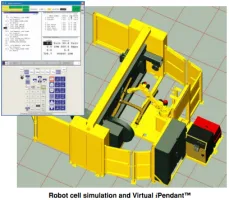

Featured Quality Inspection Robot Software:

10. How Does Quality Inspection Impact the Supply Chain?

Quality inspection has a significant impact on the supply chain, influencing everything from production efficiency to customer satisfaction.

Ensures Product Quality:

By checking products at various stages, quality inspection ensures that only items meeting the set standards reach you. This reduces the risk of defects and increases your trust in the brand.

Reduces Costs:

Catching defects early means less waste and fewer resources spent on fixing or replacing faulty products. This efficiency saves money, benefiting both the manufacturer and you.

Prevents Delays:

Identifying and solving problems early in the production process prevents delays. This means products are more likely to reach you on time, without the frustration of waiting due to quality issues.

Enhances Reputation:

Consistently delivering high-quality products strengthens a brand's reputation. A strong reputation leads to higher customer satisfaction and loyalty, making you more likely to stick with a brand you trust.

Quality inspection, therefore, plays a crucial role in keeping the supply chain smooth and reliable, ensuring you receive quality products promptly.

Need help or have questions? Contact us or book a meeting with Sven, our expert, for personalized support.